ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0066 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

GENERAL MAINTENANCE

6. Inspect and clean the actuator.

7. Install the new pneumatic positioner as follows:

a. Remove the four screws on the new pneumatic positioner and open the cover.

b. Secure the pneumatic positioner to the actuator using the 4 screws and washers.

c. Reinstall the positioner cover using the four screws.

8. Install the actuator on the butterfly valve. Refer to Butterfly Valve Replacement).

9. Install the positioner, actuator and valve assembly into the pipeline. Refer to Butterfly Valve

Replacement.

10. Connect the air tubes to the positioner and actuator ports as marked.

11. Run the unit and check the positioner, actuator and valve for leaks and proper operation.

Grooved Coupling Replacement:

Parts (TM 10-4610-309-24P):

Grooved Coupling with Gasket System

Gasket System

Materials:

Clean, dry, lint-free rags (WP 0079, Table 1, item 33)

Glycerin (WP 0079, Table 1, item 21)

Five-gallon container or drip pan

Equipment Condition:

TWPS in Standby Shutdown with Drain-Down

Replace a grooved coupling and gasket as follows:

1. Make sure the TWPS is in Standby Shutdown with Drain-Down. Refer to WP 0017.

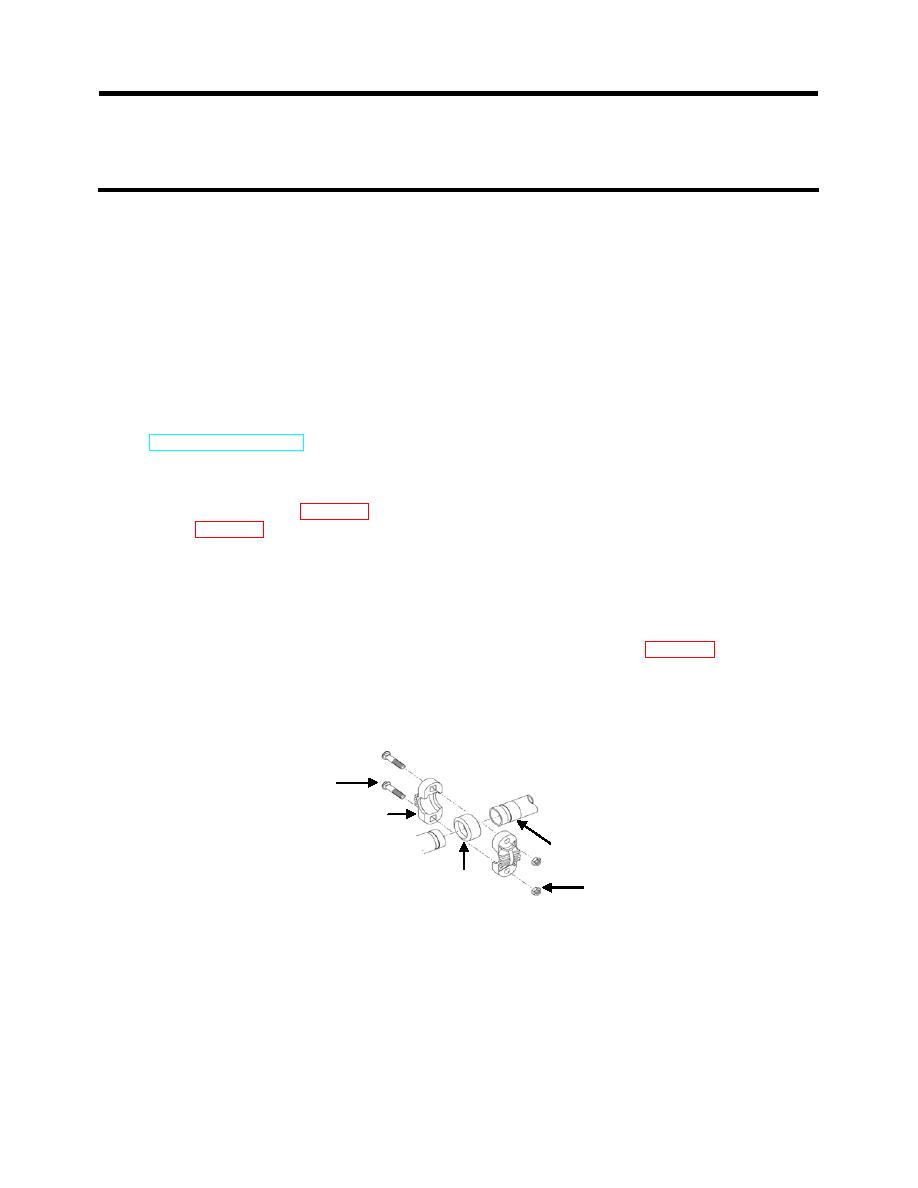

2. Remove the grooved coupling as follows (see Figure 15):

a. Place a fluid container under the coupling to catch any fluid in the line.

b. Slowly loosen the nuts and bolts that hold the coupling in place.

c. Completely remove the nuts and bolts and then remove the flexible coupling and gasket.

BOLT

COUPLING

PIPE END

GASKET

NUT

Figure 15. Grooved Coupling and Gasket.

3. Using clean, lint-free rags, clean and inspect the area where the coupling connects and check it

for obvious signs of cracks and damage.

4. Install the new grooved coupling and gasket as follows:

a. Lubricate the gasket and pipe ends with glycerin. Place the new gasket around the two

pipe halves.

b. Make sure that the gasket does not slide into the grooves on either of the pipe ends.

0066 00-16