TM 10-4610-310-14

0003 00

WATER PROCESSING FLOW- CONTINUED

floating debris and silt from the bottom. The float has 410 micron screen which provides the first stage of

filtration in the process. This part is stored inside COEI box when not in use. See Figure 1.

2. Raw water hoses

Two sections of 1-1/2 inch diameter, 25 ft. long hoses are used to pipe the water from the source to the raw

water pump. It is up to the operator to determine how many sections of hoses to use when laying out the hoses.

These hoses are the ones equipped with stainless steel camlocks.

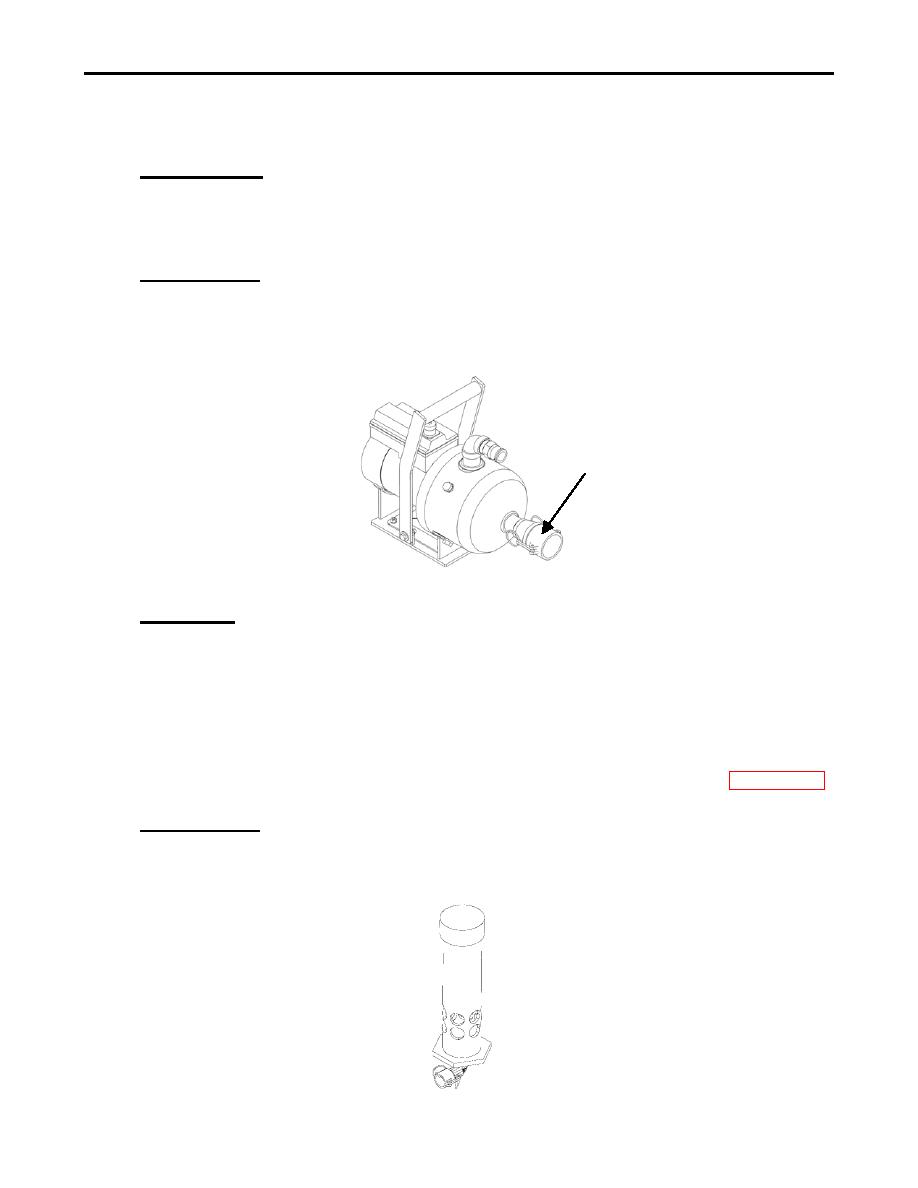

3. Raw water pump

Raw Water Pump is used to draw the water from the source into the settling tank. This pump is stored inside the

Pump module when not in use and has a 1-1/2 inch stainless steel camlocks as an intake fitting. All service

pumps are interchangeable. In case of raw water pump failure, the distribution pump, or any of the other service

pumps, can be used to replace it by switching the intake fittings. See Figure 2.

INLET FITTING

Figure 2. Raw water pump.

4. Settling Tank

The 1000-gallon collapsible fabric tank receives the raw water from the water source. When treating high

turbidity water, coagulant is injected to aid in settling of suspended particles. The water is then drawn from just

below the surface inside the settling tank through a 200-micron floating strainer. In case of chemical pump

failures, the 1000-gallon tanks can serve as reservoirs for batch treating the water with chemicals.

It has "RAW WATER ONLY" stenciled on the sides and a foam collar around the top opening to ensure proper

fill up without spilling.

The settling tank serve as a second pass reservoir when treating contaminated water source. See WP 0022 00.

5. Floating Strainer

The floating strainer is placed inside the settling tank and connected to the settling tank outlet spool piece to

draw the water from near the surface. The water is strained through a 200-micron strainer before entering the

UF module. See Figure 3.

Figure 3. Floating strainer.