TM 10-4610-310-14

0124 00

FUEL INJECTION TIMING ADJUSTMENT- continued

3. Turn flywheel counter-clockwise about 30 degrees from the T position mark.

4. Slowly turn flywheel clockwise until fuel flows from injection pump, then stop rotation.

5. Use timing marks on the flywheel to determine flywheel position. Marks are 5 degrees apart. The fuel

injection should be timed 17-18 degrees before top dead center. Therefore the notched mark should be

aligned between the third and fourth flywheel timing marks.

6. Repeat steps 4 through 6 two or three times to ensure the reading is accurate. Fuel should start flowing

from the fuel pump 17-18 degrees before TDC.

7. Adjust injection timing by adding or removing shims to the fuel pump. If fuel is injected before desired

flywheel rotation, add shims. If fuel is injected after remove shims. Each 0.1 mm (0.0039 inch) shim

changes timing by 1 degree.

8. After adding or subtracting shims, retest for proper timing.

9. Install fuel pipe onto fuel pump after timing is adjusted.

FUEL INJECTOR

Removal

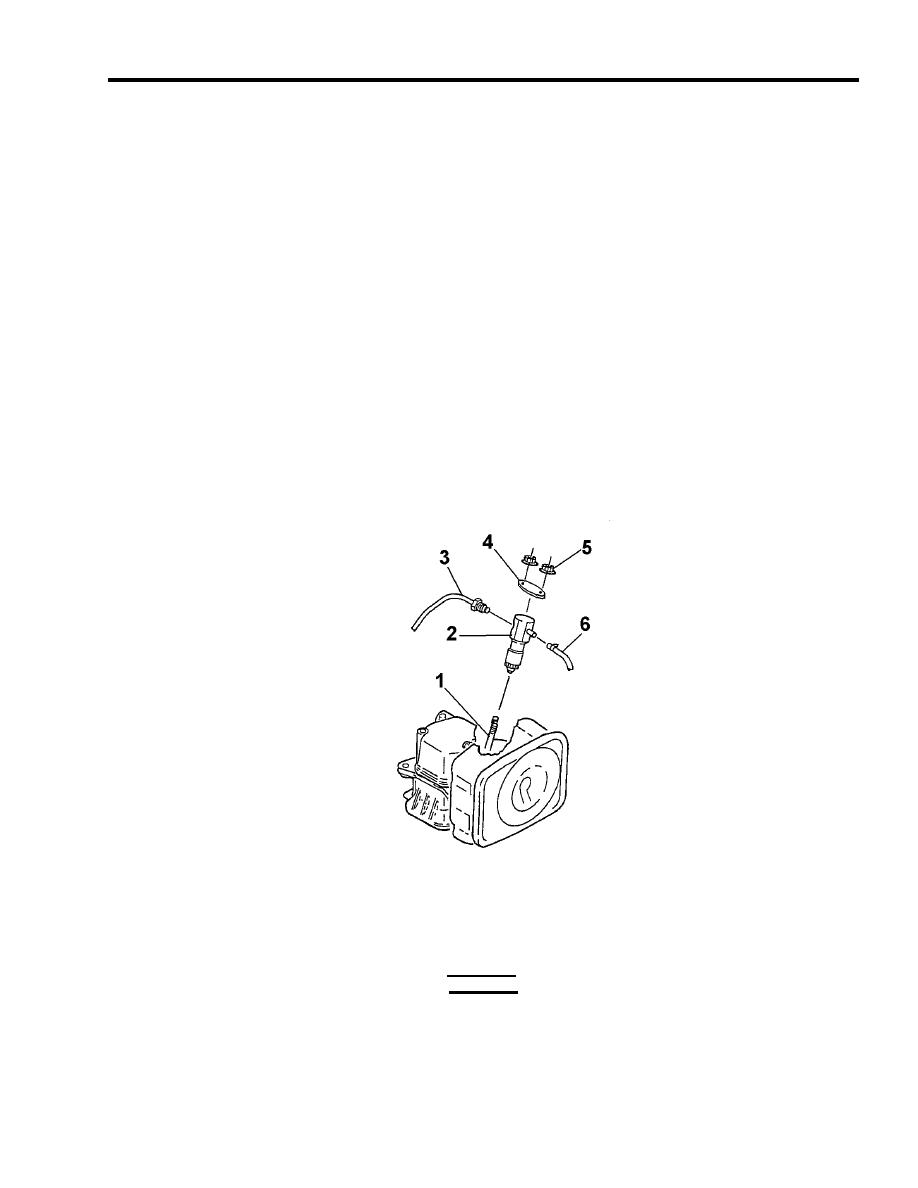

1. Remove fuel delivery line (3) and fuel return line (6) from the fuel injector (2).

2. Remove mounting nuts (5) and retaining plate (4) from studs (1).

3. Remove fuel injector (2).

Figure 6. Fuel Injector Assembly.

Inspection

1. Clean the fuel injector of any deposits.

CAUTION

Do not damage the fuel injector tip, as this will render the fuel injector unserviceable.

2. Connect the fuel delivery line (3) and fuel return line to the fuel injector (2).

3. Place the fuel injector in a suitable container.