TM 3-4230-237-10

0008 00

MAKING STB DECONTAMINATING AGENT SLURRY - Continued

Adding and Blending M2 Antiset and Silicone Antifoam Agent - Continued

VALALVENO..22

V VE NO

DECONTA INATING AP ARATUSM12A1

M

P

LOWER REEL

SERNO.

NSN

PBAUPGRADEDATE

U.S.

HEATER OFF

VVALVE NOO. 1

AL VE N . 1

REATEPTACLE OFF

HE C ER

RECEPTACLE

AND SWITCH

AND

MANIFOLD

ON

SWITCH ON

CAUTION

TO AVOID FREEZE DAMAGE KEEP PUMP

DRAIN VALVE OPEN WHEN EQUIPMENT IS

NOT IN OPERATION.

DRAIN

DRA-

OP- N

CLOSE-

CL OSD

OPE

VALVE NO. 1

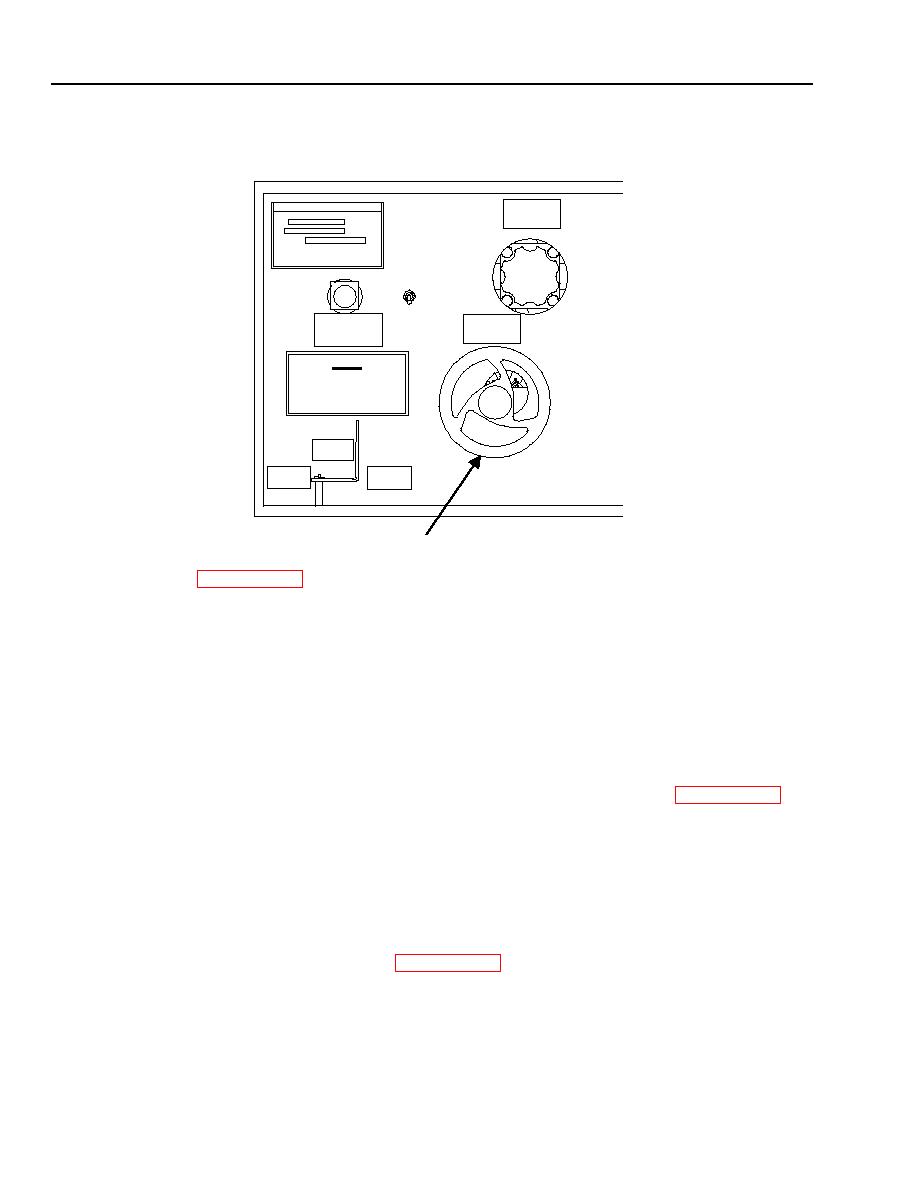

6. Start the pump unit (Page 0006 00-1). Open VALVE NO. 1 for this operation. Remove the hopper tank lid.

CAUTION

Cycle water containing M2 antiset for at least 3 minutes. The M2 antiset must be completely dissolved.

NOTE

If the M2 antiset is caked, it must be crushed as finely as possible before adding it to the water in the tank

unit assembly.

7. Add the M2 antiset and silicone antifoam agent. Operate for 3 minutes to fully blend these additives.

8. To prepare STB decontaminating agent for loading, open the 26 cans of STB decontaminating agent (Page 0028 00-2,

item 8).

NOTE

Before starting the loading and blending operations, break up the large lumps of STB to prevent clogging

of the lines and to ensure the best possible water-slurry mixture. To prevent damage to the equipment, do

not strike the metal drums containing the STB decontaminating agent against the tank or any other part of

the tank unit.

9. Add the 1,300 pounds of STB decontaminating agent (Page 0028 00-2, item 8) in one continuous operation. When

loading agent, see that hopper does not run out of STB decontaminating agent. If the supply of agent is exhausted before

loading is completed, the slurry in the tank may foam. Stop foaming by adding additional silicone antifoam agent.

CAUTION

After the slurry is blended, it must be agitated constantly until used.

10. After blending is complete, replace tank lid. Agitate the slurry mixture.

0008 00-4