TM 3-4230-237-10

0008 00

MAKING STB DECONTAMINATING AGENT SLURRY - Continued

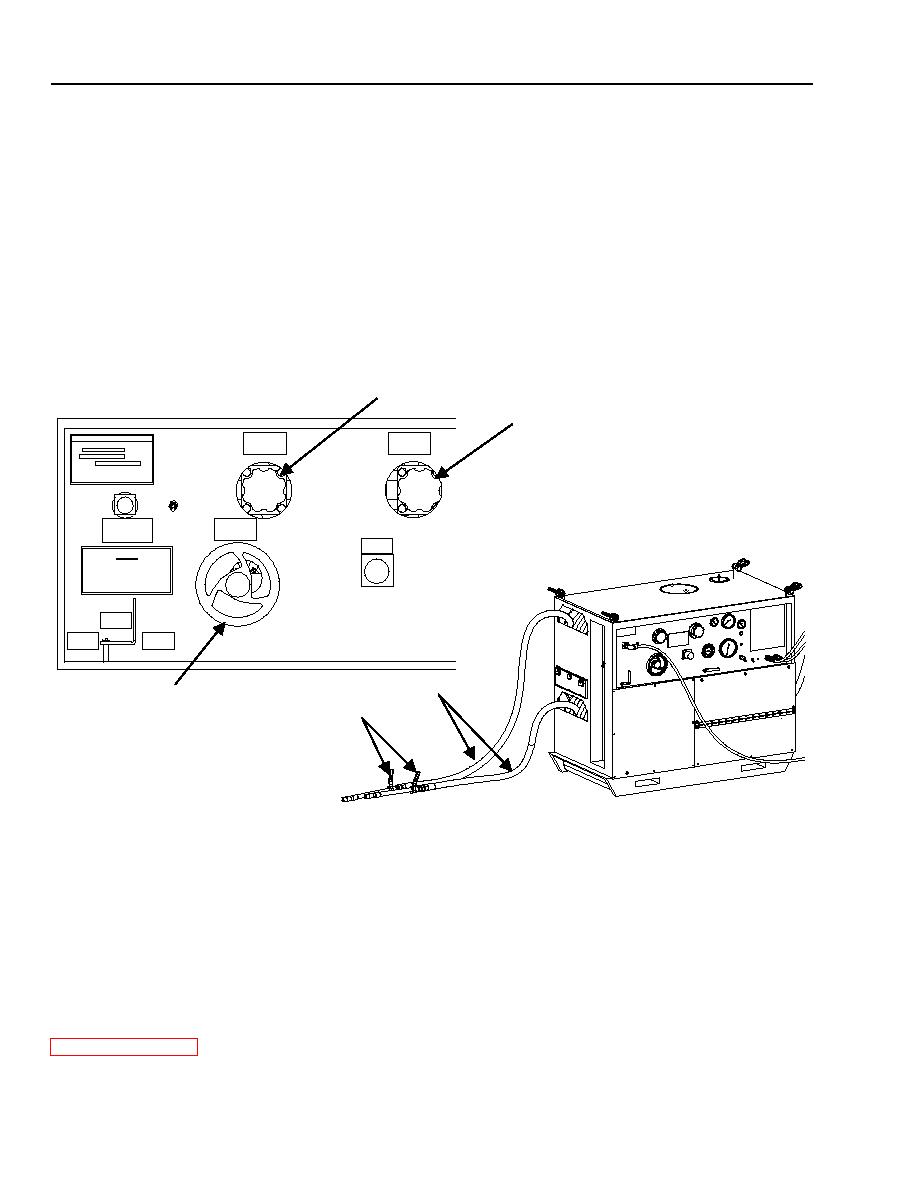

Spraying Slurry From Tank - Continued

CAUTION

The agitator-blender hose will contain slurry. Clean this hose before storing it on the tank unit.

NOTE

If only one discharge hose is to be used for spraying slurry, agitation of the slurry in the tank may continue.

Open VALVE NO. 3 to the upper discharge hose. If adequate pressure is maintained (105 psi), continue

both agitation and discharge. If not, stop agitation.

4. Disconnect the agitator-blender hose (5) from the pump unit. Cap the upper discharge pipe and disconnect the hose from

the agitator pipe (7) on the tank unit.

VALVE NO. 2

VALVE NO. 3

VALALVENO..22

V VE NO

DECONTAMINATINGAPPARATUSM12A1

VALVE NO.3

UPPEVEEEO.

VAL R R NL

3

LOWER REEL

SERNO.

NSN

PBAUP RADEDATE

G

U.S.

HEATER OFF

VVALVE NOO. 1

ALVE N.1

REATEPTACLE OFF

HEC ER

HO

RECEPTACLE

AND SWITCH

AND

MANIFOLD

ON

H

SWITCH ON

SLAVEE

SLAV

RECEPTACLE

CAUTION

TO AVOID FREEZE DAMAGE KEEPPUMP

DRAIN VALVE OPEN WHEN EQUIPMENT IS

NOT IN OPERATION.

OPPN

OE-

DRAIN

DRA-

VALLVEMEO.44

VA

VRI NO.

EN

OP- N

CLOSS-

CLO ED

P

OPE

8

VALVE NO. 1

9

5. Unreel the discharge hoses (8).

6. Open VALVES NO. 1, 2, 3 and gun assembly valves (9).

NOTE

The PRESSURE GAGE indication while spraying slurry may vary between 60 and 120 psi.

7. Adjust the orifice and deflector assembly to vary the spray pattern from stream to fine spray mist. The pump discharge

pressure gage should indicate approximately 105 psi pressure when slurry is being sprayed.

8. After the spraying mission is complete, flush, drain, clean, and store the apparatus according to procedure outlined in

0008 00-8