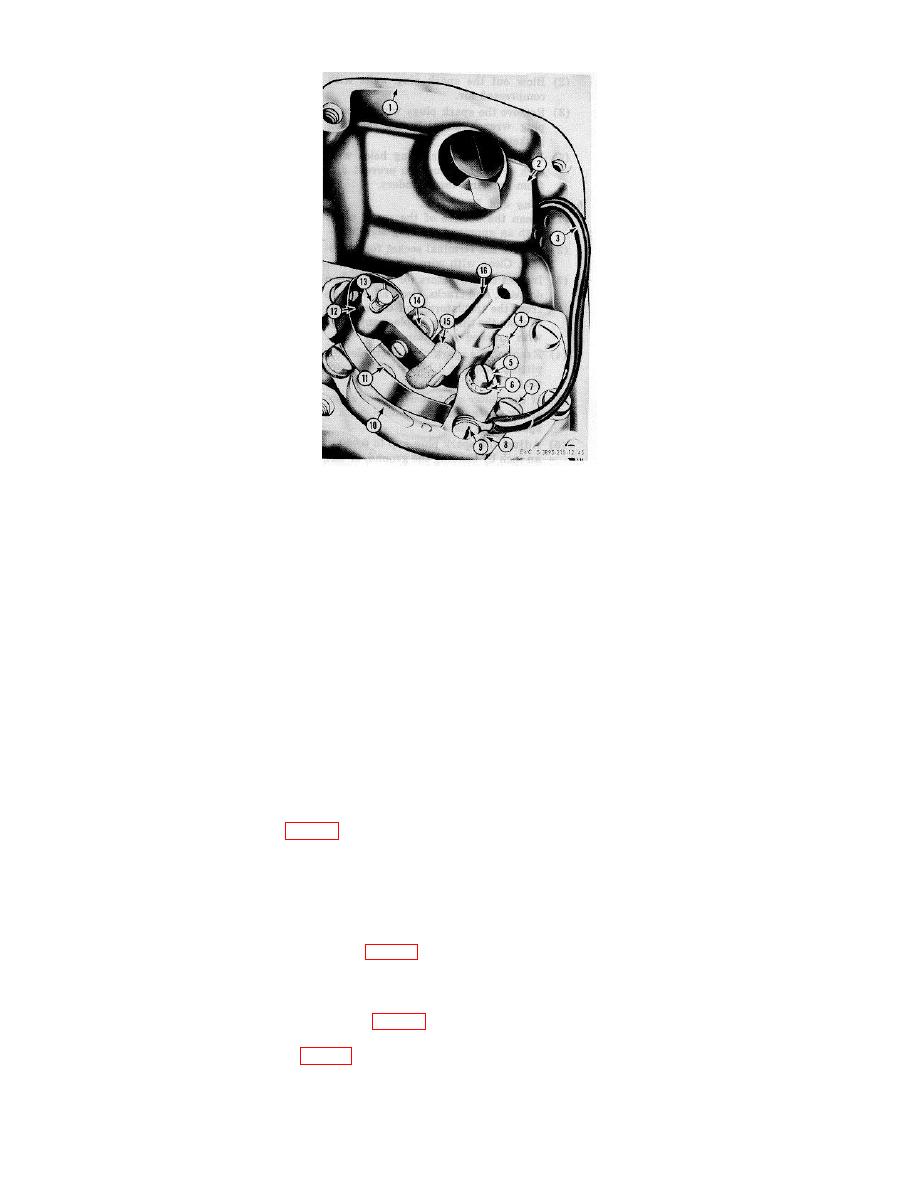

1

Housing

5

Screw

9 Screw

13

Pivot snapring

2

Coil

6

Lockwasher

10 Plate

14

Contact

3

Ground Wire

7

Screw

11 Screw

15

Feltwick

4

Camwick

8

Plate

12 Breaker arm

16

Rotor shaft

Figure 28. Magneto adjustment

and is driven off the timing gears at camshaft speed. The magneto is enclosed in a metal frame, cap, and end

cover. Threaded cable outlets are provided for connection to the spark plug lead shielding. All the interior

metal is interconnected and grounded to provide radio shielding. The magneto armature is a one-piece

magneto rotor that rotates between the pole pieces of a laminated iron frame causing an induced current to

flow in the primary circuit of the coil, during the time the contact points are closed. When the points open, the

primary circuit is broken, instantly collapsing the field and inducing the secondary circuit of the coil

to produce the intense ignition spark for startings. An impulse coupling is provided which makes possible the

production of a spark at cranking speed equal to that produced when the engine is running. The impulse

consists of a hub and shell connected by a torsion type spring. Through this device, the magneto armature is

held back while the engine is turned over to just past top dead center, at which instant the pawls of the coupling

are released by the pawl stop pin, causing the power coil spring to snap the magneto armature forward at high

speed. This produces an intense spark, automatically retarded to prevent kick-backs. When the engine starts,

the pawls are disengaged by centrifugal action of the drive gear,

causing the coupling to act as a direct drive.

b. Adjustment.

(1) Remove screw (8, fig. 18) and lockwasher securing the magneto stop switch wire.

(2) Remove the four connectors (20) securing the spark plug cables and disconnect the cables, tagging

each so they can be replaced in their proper sockets in the magneto.

(3) Remove the four screws (11) and lockwashers securing the end cover (12) and remove the end

cover and gasket (13).

(4) Rotate the crankshaft with the starting crank until the breaker arm is riding on the high spot of the

camshaft and the breaker points are wide open.

(5) Loosen the locking screws (7, fig. 28) on the contact plate so that the plate is movable.

(6) Insert the end of a small screwdriver into the adjusting slot at the bottom of the contact plate (10)

and open or close the breaker points by moving the contact plate until the clearance is .015

checked with a feeler gage.

(7) Tighten the locking screws (7 and 11) and recheck the breaker point gap (14) to make sure it has

not changed.

(8) Position gasket (13, fig. 18) and end cover (12) on the magneto and secure with four lockwashers

and screws (11).

AGO 6871A

50