Engine

Disassembly and Assembly

4.

If the fuel injection nozzle can not be removed with a

maximum torque of 17 N•m (150 Ib. in.) on the screw of

tooling (A), remove tooling (A).

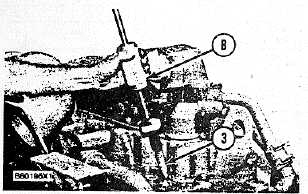

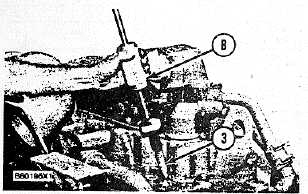

5.

Remove the protective cap from fuel injection nozzle

(3), and install tooling (B) as shown.

NOTICE

Hold tool (B) so the center line of the tool is if

alignment with the centerline of fuel injector nozzle

(3). This will prevent distortion of the nozzle which

can cause it to bend or break of during removal.

6.

Remove the fuel injection nozzle with tool (B).

7.

If tool (B) was used to remove the fuel injection

nozzle, make a replace of the nozzle.

8.

If tool (A) was used to remove the fuel injection

nozzle, remove the carbon dam seal on the end of the

nozzle.

Install Fuel Injection Nozzles

Tools Needed

A

B

C

6V4089

Reamer*

1

8S2245

Cleaning Tool Group

1

6V4979

Carbon Seal Tool

1

*Part of 6V7020 Nozzle Puller Group

NOTE: The illustrations which follow are of a 3306

Engine.

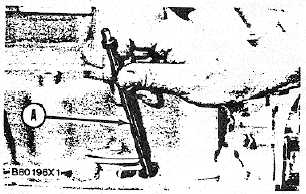

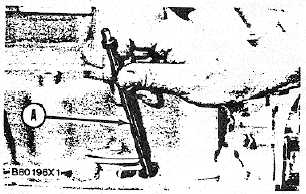

1.

Use tool (A) to clean the bore for the fuel injection

nozzle. Use an open end wrench or tap driver to turn

tool (A).

2.

Make reference to Special Instruction, Form No.

SEHS7292, for the use of tooling (B). Clean the fuel

injection nozzle with tooling (B).

11