TM 10-4610-232-34

d. Replace bearings(13, 14, 23, 26 and 28).

e. Replace any other worn, damaged or unserviceable parts.

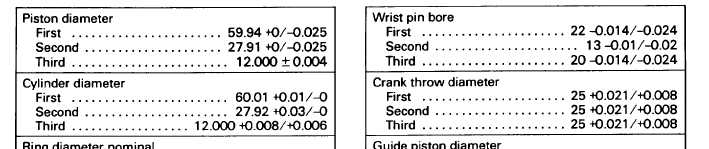

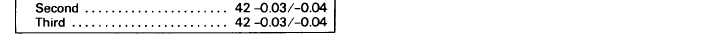

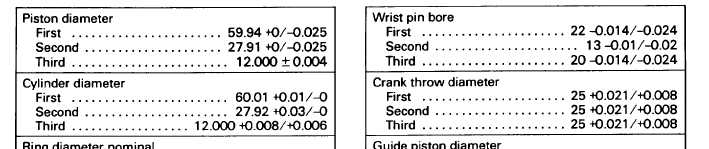

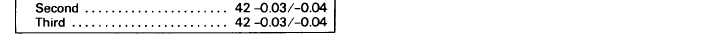

f. Refer to Table 3-1. Replace any component(s) exceeding clearance or tolerance limits.

Table 3-1. Compressor Clearance Tolerance Limits

a. Refer to Figure 3-6 and install new seals (15 and 16) in crankcase (31) and end cover (11).

b. Using a suitable press, press new outer races for bearings (13 and 14) into end cover (11) and crankcase (31).

WARNING

Use protective gloves when handling heated parts.

CAUTION

Do not heat bearings with a torch. Uneven or excessive heat will damage the

bearings beyond use.

NOTE

Install inner race bearings in one continuous motion. Do not stop.

c. Heat and install inner race of bearing (28) onto crankshaft (30). Position it at the point marked during removal.

Install spacer (29). Lubricate the outer race of bearing (28) (in connecting rod (27) bore) and install the connecting rod on

the inner race of bearing (28).

d. Install spacers (25), connecting rod (24), and bearing (26) as in para. c.

e. Install spacers (22), connecting rod (21), and bearing (23) as in para. c.

f. Install counterweight (20) with the machined surfaces facing the connecting rods and secure with socket head

screw (19), washer (18) and locknut (17).

3-11