TM 10-4610-240-10

TM 08580C-10/1

T.O. 40W4-13-21

(7) If after second sampling test, water is not clear, increase POLYMER chemical feed control knob setting by

5.

NOTE

The setting of 60 or 20 ml/min set earlier was only to prevent overdosing of polymer. This rate may be

adjusted during operation to improve clarity

(8) Run ROWPU for 5 minutes, and repeat steps (4) and (5). If both bullseye and black disc can be seen

clearly, proceed to step j; if not, proceed to step (9).

(9) Increase control knob setting by 5.

(10) Repeat steps (8) and (9) until water is clear.

NOTE

Unless source water is noticeably turbid, it should not be necessary to increase POLYMER setting beyond

50.

j. Final Adjustments.

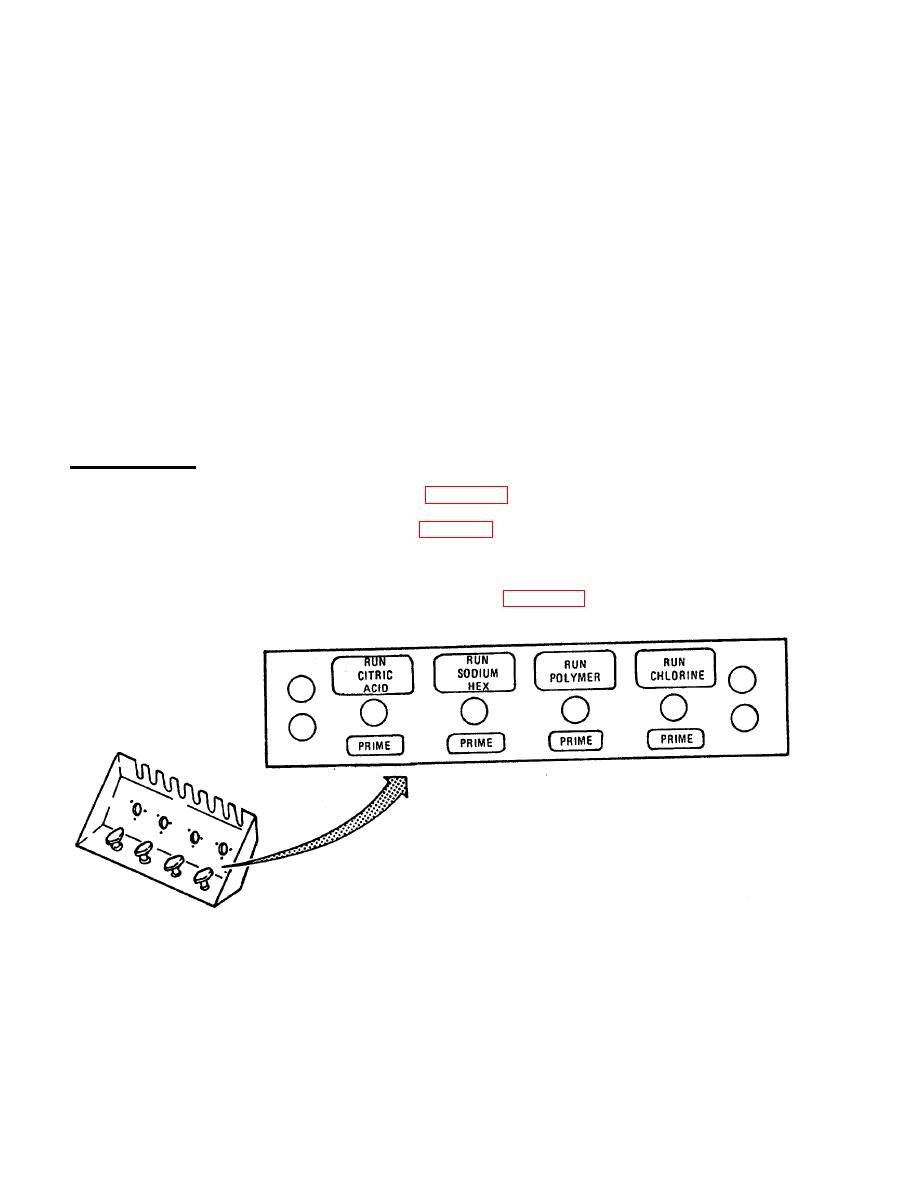

(1) Set SODIUM HEX valve to RUN position (figure 2-10).

(2) Check that the vent product water valve (figure 2-6) is in the OPEN position. The vent product water valve

allows air to escape from the product water line and lowers product water pressure. It should be closed once product

water has been produced.

(3) Check that the REGULATE PRODUCT flow valve (3, figure 2-64) is fully open.

FIGURE 2-63. NAME PLATES

2-65