TM 10-4610-240-10

TM 08580C-10/1

T.O. 40W4-13-21

(5) When solution flow has been established in SODIUM HEX and CHLORINE hoses, calibrate the flows as

follow:

(a) Set the SODIUM HEX control knob to 50.

(b) Remove return hose from chemical container.

(c) Catch chemical in 100 ml graduated cylinder (Storage Box No. 3).

(d) Adjust control knob to approximately 60 ml/min flow. Record knob setting for future reference.

(e) Calibrate chlorine flow in same way.

(f) Do NOT turn RUN/PRIME valves to RUN; leave them in PRIME position.

(6) Leave CITRIC ACID control knob at maximum setting; no calibration is required for CITRIC ACID flow.

RUN/PRIME valve remains in PRIME position throughout normal operation.

(7) With both raw water pumps working, and the chemical feed pump running, set POLYMER pump valve

from PRIME to RUN.

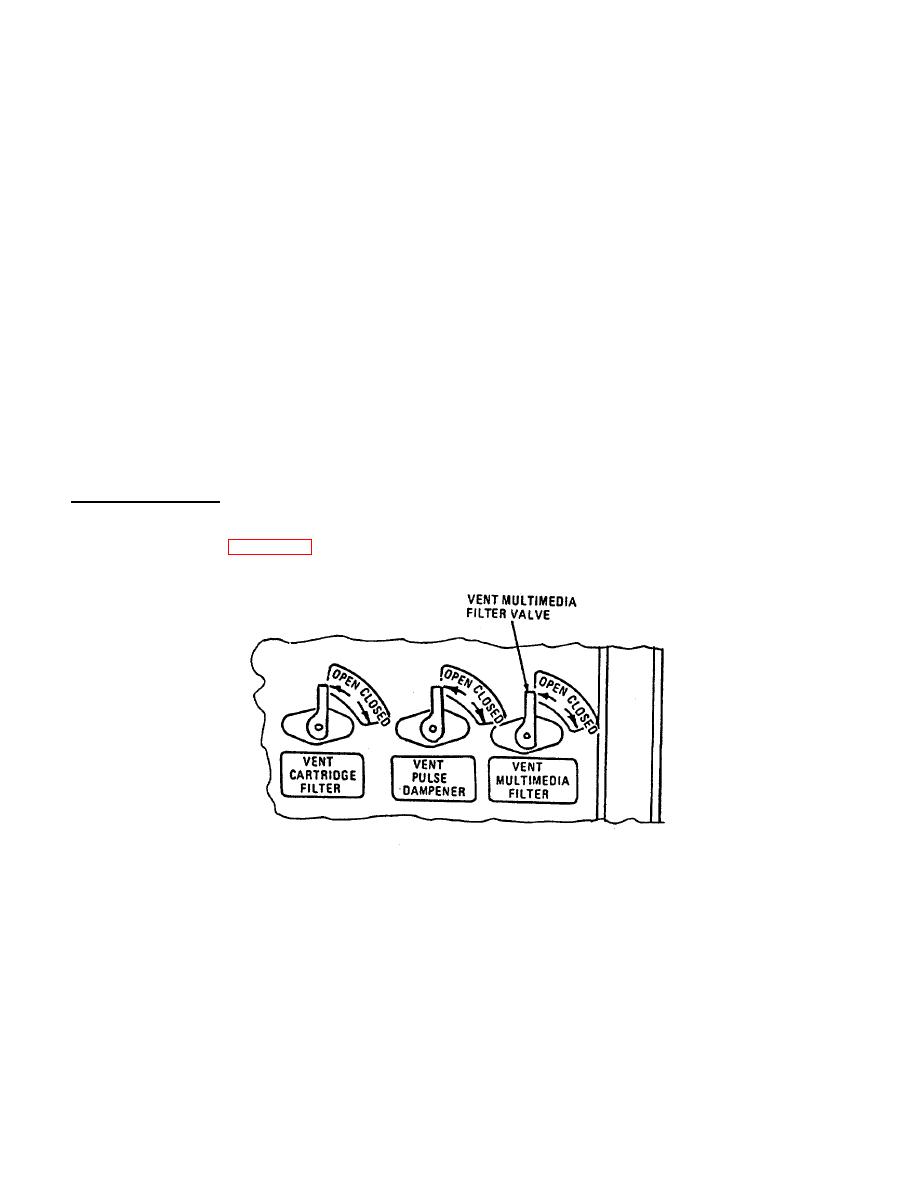

f. Vent Multimedia Filter . Vent multimedia filter and check for vent line blockage as follows:

(1) Set VENT MULTIMEDIA FILTER valve, VENT PULSE DAMPENER valve, and VENT CARTRIDGE

FILTER valves to CLOSE (figure 2-54).

FIGURE 2-54. MULTIMEDIA FILTER VENT VALVE

(2) Set VENT MULTIMEDIA FILTER valve to OPEN.

NOTE

There should be air venting out of the pipe as the multimedia filter fills, followed by a steady stream of

water when the filter is full. If not, the vent line is probably blocked by a small piece of filter media. Notify

unit maintenance.

(3) Set VENT MULTIMEDIA FILTER valve to CLOSE as soon as a full stream of water flows out of vent pipe

(located at bottom right-hand front of trailer, below R.O. pump belt guard).

2-60