ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0066 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

GENERAL MAINTENANCE

3) Holding the pistons in place so that they do not fall out of the actuator body,

position the actuator body so that one piston head is on the working surface and

the other piston head is facing up.

4) Push firmly on the top piston to push the pistons into the actuator body until both

pistons engage with the teeth on the pinion shaft.

5) Check that the piston O-ring on both of the pistons has not slipped out of position

so that it sticks out between the piston head and the end of the actuator body. If

an O-ring is out of position, remove the pistons, replace the O-ring if damaged or

reseat the existing O-ring on the piston head, and reinsert the pistons into the

bore of the actuator.

g. Reposition the pinion shaft to fully retract the pistons into the body as follows:

1) Set the actuator body on the work surface with the base plate down.

2) Insert the shaft adapter into the top of the pinion shaft.

3) Insert a suitable tool (such as the nose of a needle nose pliers) into the shaft

adapter and turn the pinion shaft clockwise as far as it will go.

4) Remove the shaft adapter from the top of the pinion shaft.

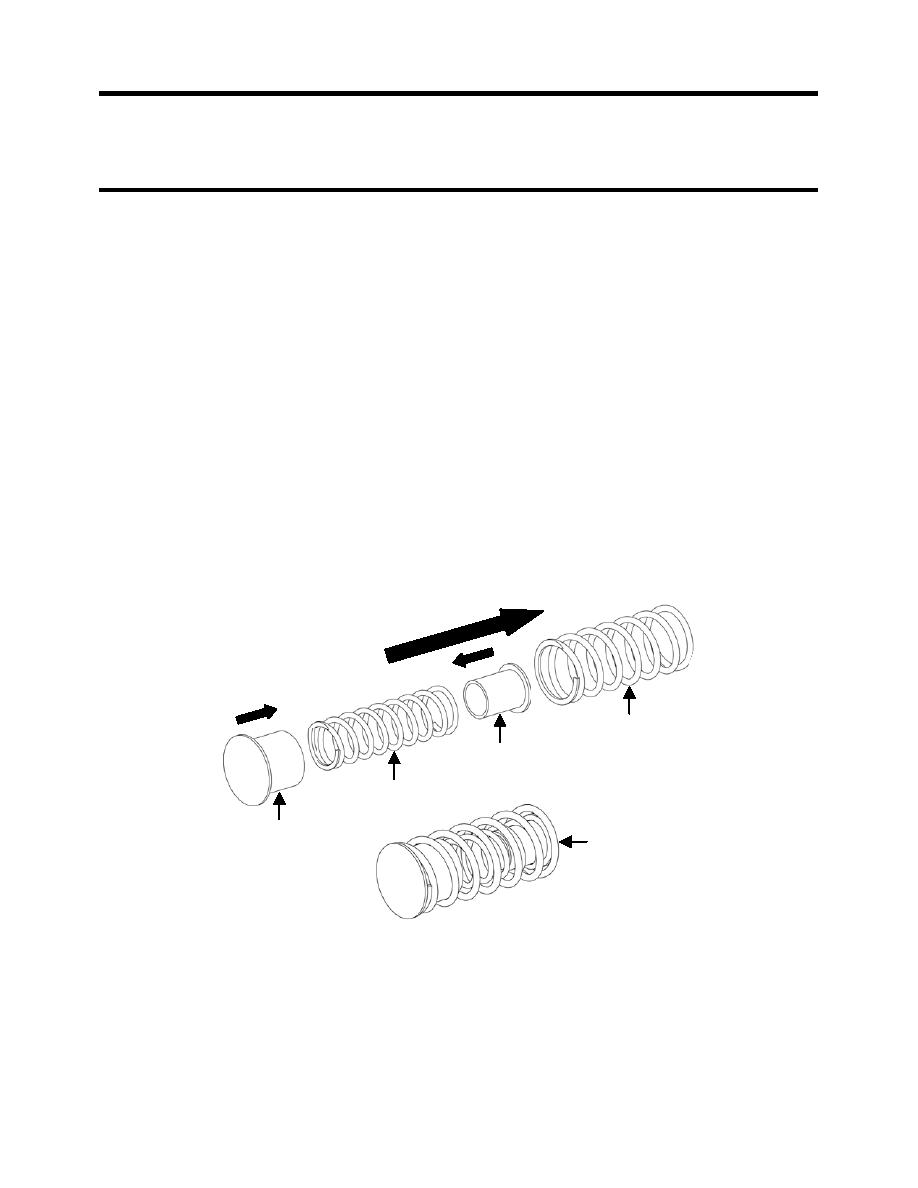

h. Assemble the springs as follows (see Figure 22):

1) Insert one inner guide into one end of an inner spring.

2) Insert the other end of the inner spring into the open end of a sleeve guide.

3) Insert the inner guide end of the inner spring into one end of an outer spring.

4) Repeat for each of the other seven spring assemblies.

OUTER SPRING

INNER GUIDE

INNER SPRING

SLEEVE GUIDE

ASSEMBLED SPRINGS AND GUIDES

Figure 22. Actuator Spring Assembly.

i.

Assemble the springs and end caps to the actuator body as follows (see Figure 23):

1) Set the actuator body up on one end of the body.

2) Set four assembled spring assemblies, sleeve guide down, into the cavity of the

piston head.

0066 00-24