ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0066 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

GENERAL MAINTENANCE

3) Check that the shaft bottom O-ring hasn't slipped out of position so that it sticks

out the bottom of the base plate. If the O-ring is out of position, remove the shaft,

replace the O-ring if damaged or reseat the O-ring on the shaft and reinsert the

shaft in the base plate.

4) Carefully lower the body of the actuator over the top of the pinion shaft and onto

the base plate, finishing with a firm push to make sure that the top of the shaft is

fully seated in the body bore.

5) Check that the holes in the base plate line up with the holes in the bottom of the

actuator body. If they do not, rotate the base plate 90 so that the holes do line

up.

6) Secure the base plate to the body using the four cap head screws and spring

washers.

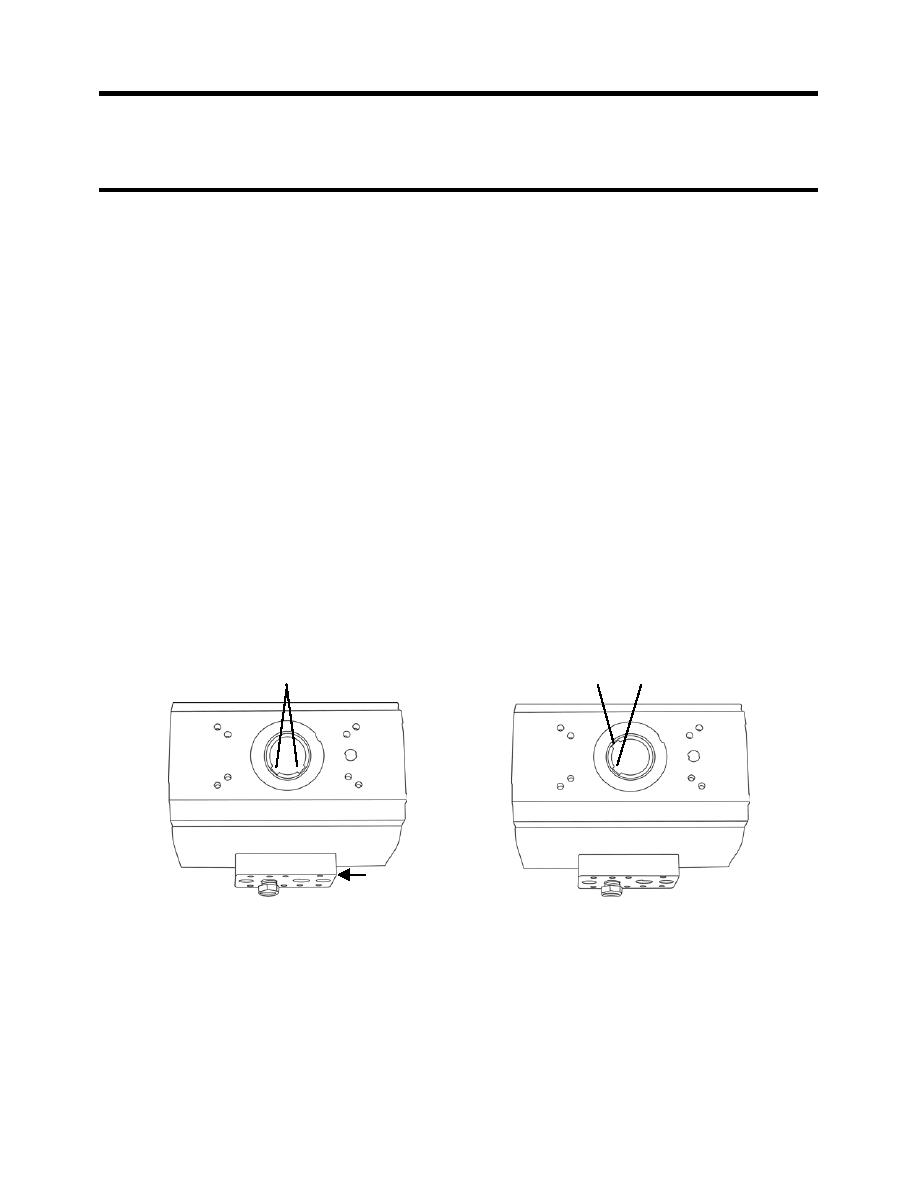

d. Position the pinion shaft as follows:

1) Set the actuator on its base plate with the air connection plate facing you.

2) Insert the shaft adapter into the top of the pinion shaft.

3) If the actuator is for use on a normally open valve (V-111, V-112, V-201, or V-

202) insert a suitable tool (such as the nose of a needle nose pliers) into the

shaft adapter and turn the pinion shaft so that both pinion shaft keyways are at a

45 angle to the air connection plate (see Figure 21).

4) If the actuator is for use on a normally closed valve (V-113, V-401, or V-402)

insert a suitable tool (such as the nose of a needle nose pliers) into the shaft

adapter and turn the pinion shaft so that both pinion shaft keyways are at a 45

angle to the left end of the actuator body (see Figure 21).

5) Remove the shaft adapter from the top of the pinion shaft.

PINION SHAFT KEYWAY POSITION

PINION SHAFT KEYWAY POSITION

FOR A NORMALLY OPEN VALVE

FOR A NORMALLY CLOSED VALVE

BEFORE ACTUATOR PISTONS ARE INSTALLED

BEFORE ACTUATOR PISTONS ARE INSTALLED

AIR CONNECTION PLATE

Figure 21. Position of Actuator Pinion Shaft Keyways Prior to Installing Pistons.

e. Lubricate the pinion shaft teeth with molybdenum disulfide grease.

f. Assemble the pistons to the actuator body as follows:

1) Lubricate the piston teeth with molybdenum disulfide grease.

2) With the air connection plate facing you, insert the right piston into the bore of the

actuator body with its backing pad toward you and insert the left piston into the

bore with its backing pad away from you (see Figure 20).

0066 00-23