ARMY TM 10-4610-309-14

MARINE CORPS TM 10802A-14/1

0066 00

TACTICAL WATER PURIFICATION SYSTEM (TWPS)

UNIT MAINTENANCE PROCEDURES

GENERAL MAINTENANCE

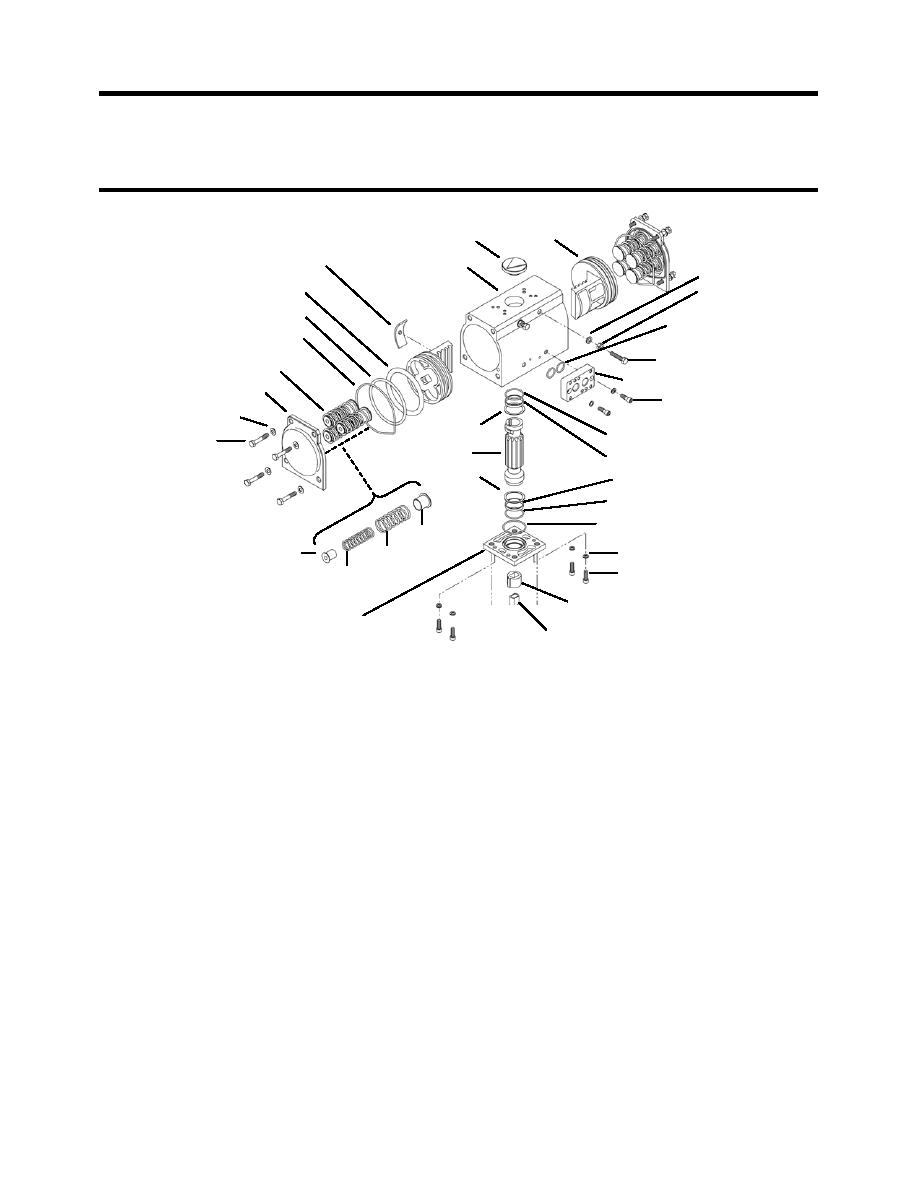

PISTON

POSITION INDICATOR CAP

TRAVEL STOP

ACTUATOR BODY

PISTON BACKING PAD

SEALING WASHER

PISTON O-RING

TRAVEL STOP

LOCK NUT

PISTON SUPPORT RING

AIR CONNECTION

END CAP O-RING

PLATE O-RING

TRAVEL STOP BOLT

SPRING ASSEMBLY

AIR CONNECTION PLATE

END CAP

CAP HEAD BOLT

FLAT WASHER

AND WASHER

TOP SPACER

SHAFT TOP O-RING

END CAP BOLT

PINION SHAFT

TOP BEARING

BOTTOM SPACER

BOTTOM BEARING

SHAFT BOTTOM O-RING

BASE PLATE O-RING

SLEEVE GUIDE

INNER GUIDE

SPRING WASHER

OUTER SPRING

INNER SPRING

BASE PLATE CAP HEAD BOLT

SHAFT ADAPTER

BASE PLATE

ADAPTER SLEEVE

Figure 20. Actuator Disassembly.

2. Clean all the disassembled components.

3. Remove and replace the following components with new components (see Figure 20):

a. Shaft top O-ring

b. Top bearing

c. Top spacer

d. Shaft bottom O-ring

e. Bottom bearing

f. Bottom spacer

g. Base plate O-ring

h. Piston O-ring (one on both of the pistons)

i. Piston support ring (one yellow green ring on both of the pistons)

j. Piston backing pad (one on both of the pistons)

k. End cap O-ring (one on both of the end caps)

l. Air connection plate O-rings (two)

4. Reassemble the actuator as follows (see Figure 20):

a. Lubricate the body bore (inside of the actuator body) with molybdenum disulfide grease.

b. Lubricate all O-rings, bearings, and support rings with molybdenum disulfide grease.

c. Assemble the pinion shaft and base plate to the actuator body as follows:

1) Coat the bottom of the pinion shaft with molybdenum disulfide grease.

2) Carefully insert the pinion shaft into the base plate bore, finishing with a firm push

to make sure that the shaft is fully seated in the bore.

0066 00-22