TM 10-4610-310-14

0010 00

CHEMICAL STORAGE - continued

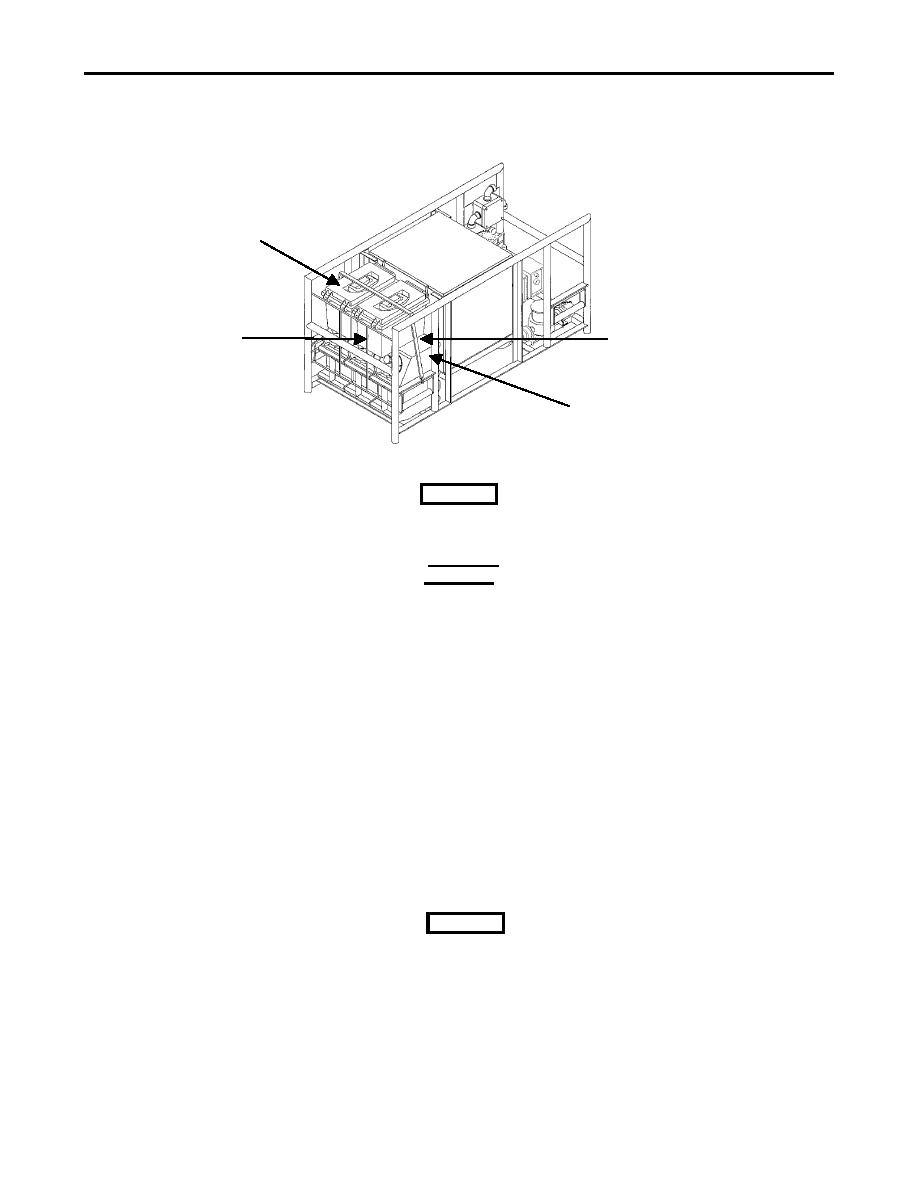

Note the orientation in which the chemical tanks are stored. They are secured with a bungee cord. See Figure 2.

SODIUM

HYPOCHLORITE

CALCIUM

BUNGEE CORD

HYPOCHLORITE

(M229)

CHEMICAL

TANKS

Figure 2. Chemical Storage On The Module.

WARNING

See each chemical Material Data Safety Sheet for information regarding the specific hazards

associated with each chemical. Injury to personnel could result.

CAUTION

To prevent serious damage to the Reverse Osmosis (RO) membrane elements, never allow

water that contains chlorine to be introduced to the RO element module. Damage to

membrane elements will result.

Only the chlorine injection is mandatory. The other chemicals are to be injected depending

on source water conditions.

Sodium metabisulfite Mixing Instruction

NOTE

The Sodium metabisulfite container includes a double-ended scoop: a Large (tablespoon) and a small

(teaspoon) scoop.

1. If the raw water contains chlorine, sodium metabisulfite (M323) injection is required to neutralize it.

2. Add 50 grams (or two large scoops) of sodium metabisulfite (M323) for each parts per million (ppm) of

chlorine in the source water to the coagulant/sodium metabisulfite chemical tank T6. Chemical is identified

with a green diamond.

WARNING

To avoid injury from contact with the cleaning chemicals, be sure to wear the personnel

protective equipment (goggles, gloves, and apron).

3. Fill the appropriate tank with potable product water half way.

4. Make sure all caps are closed and tight on the tank before shaking. Mix solution well by shaking the

chemical tank T6.

5. Finish filling the chemical tank T6 with product water.

6. Open vent cap on the chemical tank T6 to expose the vent hole.