TM 10-4610-310-14

0010 00

CHEMICAL INJECTION PUMP ADJUSTMENT - continued

9. If the TDS is less than 1000 milligrams per Liter (mg/L) and the chlorine residual is on par with TB MED 577

instructions, the water is suitable for storage and distribution.

10. Connect the other end of the 10-foot (3.05-meter) 1-inch (2.54 cm) diameter potable water hose (white) to

the inlet spool piece of the product water tank to store the product water.

BATCH SOLUTION

If the chemical injection pump fails to inject any chemical into the system after troubleshooting, chemicals must

be manually added to the product or settling tank as needed. Use Table 1 to add chemicals to the 1000-gallon

tanks.

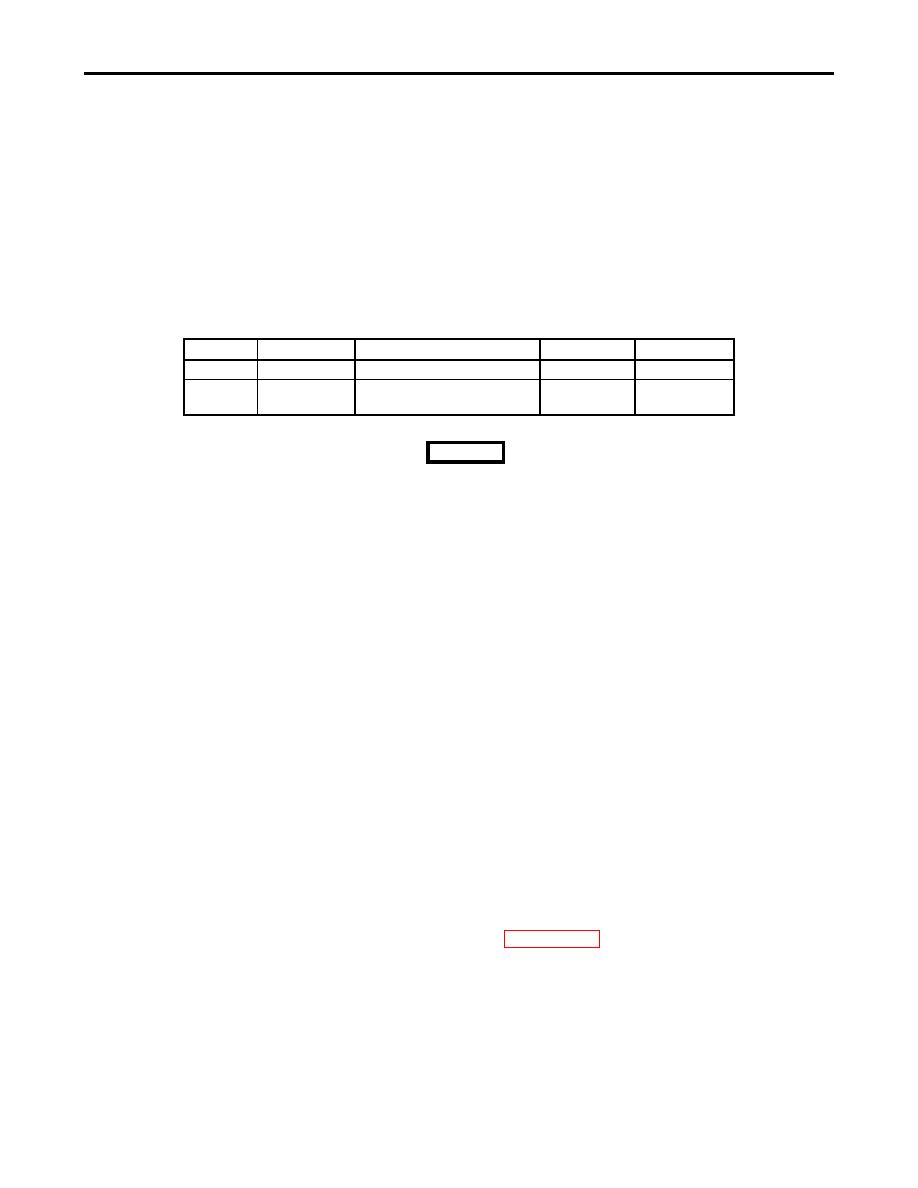

Table 1. Batch Chemical Dosage.

Tank

Coagulant

Sodium Metabisulfite

Antiscalant

Hypochlorite

(gal)

(ml)

(small scoop)

(ml)

(g)

2 (or 16 g) per ppm of

chlorine

1000

50

10

20

WARNING

The chlorine level must be monitored periodically to ensure prevention against contamination. Illness may result

from drinking contaminated water.

After Bisulfite addition, water must be tested to ensure chlorine has been neutralized. Add sodium Metabisulfite,

sample the water and repeat procedure as necessary.

CHEMICAL INJECTION PUMP PRIMING

1. Ensure the vents on the chemical tanks are open.

2. Ensure that there are sufficient solutions in the tanks and air is not being sucked in.

3. Ensure all tubings and connections are free of blockage and kinks. Ensure air is not being sucked in

through loose connections.

4. Ensure all tubings are serviceable.

5. Ensure that the pump is running and set the speed and stroke knobs to 80 and 80.

6. Pull out the priming valve on the pump and rotate a quarter turn to begin priming. Observe the relief

valve for fluids squirting out.

7. Lift up the chemical tank and place it on top of the cleaning tank. Observe the relief valve for fluids

squirting out.

8. Keep the chemical tank elevated and remove the tubing from the inlet end of the pump and allow the

chemical to drain out into a suitable container. If fluid is not observed, trace the tubing back to the

chemical tank for any blockage.

9. Remove the blocked tubing and clean or replace it. See WP 0108 00.

10. Prime the pump and pull out and rotate the priming knob a quarter of a turn to close it.

11. Ensure that the chemical pump settings are reset for normal operation after being primed.

END OF WORK PACKAGE