TM 10-4610-310-14

OPERATOR INSTRUCTIONS

LIGHTWEIGHT WATER PURIFIER

MAINTAINING NORMAL OPERATION

GENERAL

This work package contains information and instructions for maintaining normal operation of the Lightweight

Water Purifier (LWP).

NORMAL OPERATING PARAMETERS

During operation of the LWP the normal operating parameters will be followed. Any deviations will be an

indication that something is malfunctioning.

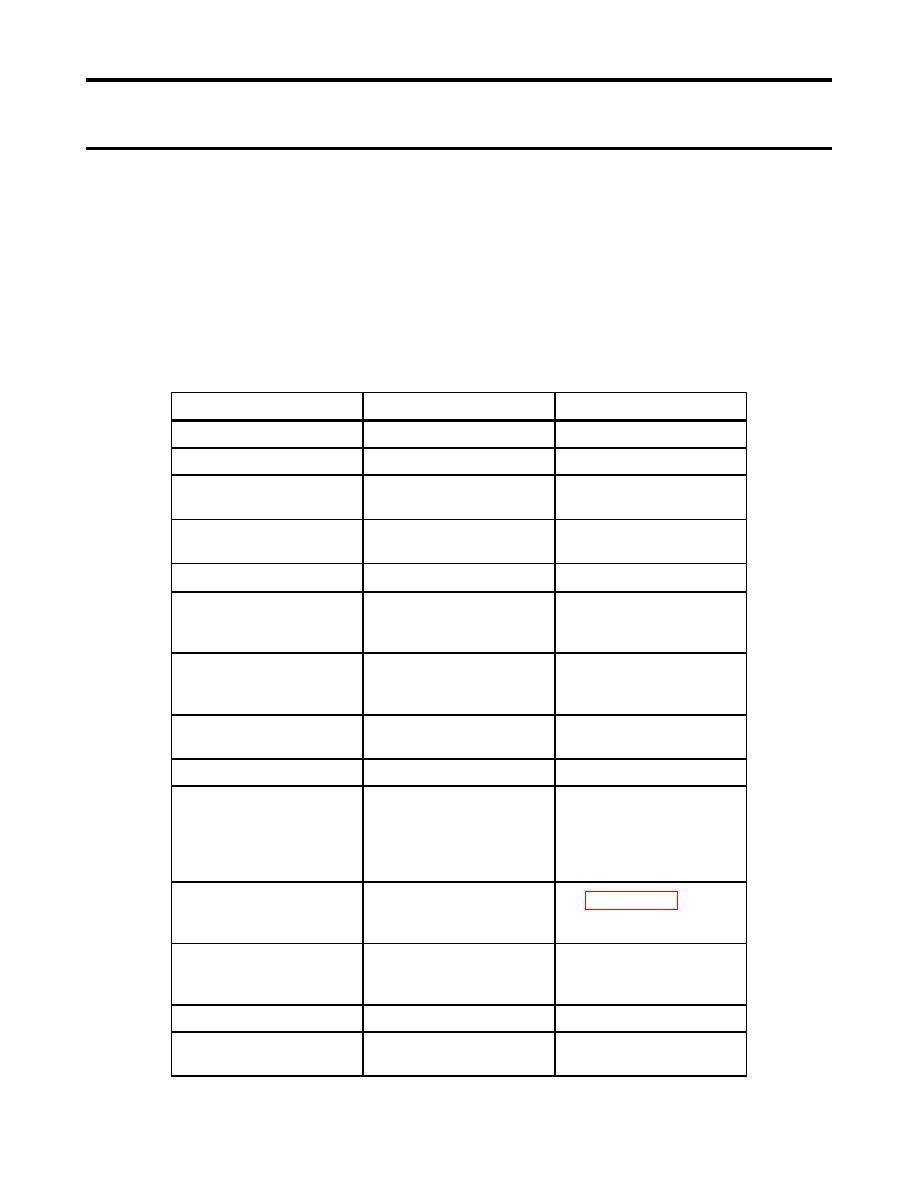

Table 1 provides the normal range of operating parameters and normal operations. Consult troubleshooting

sections if normal parameters are not met.

Table 1. Normal Operating Parameters.

Description

Display/Condition

Remarks

Feed pressure (UF)

35 60 psi

See Figure 1.

Differential pressure (UF)

0 30 psi

See Figure 1.

Backwash pressure (UF)

35 60 psi (occurs 3

See Figure 1.

times per hour)

Fabric filtrate tank (UF)

Should be at least half full

Will not be full during

cleaning cycle

Never exceed 100 F

UF feed temperature

Varies with source water.

Backwash cycle and fast

Rejects for 7 seconds

3 cycles of this per each

flush cycle (UF)

stops for 3 seconds.

cartridge. (occurs once

every 15 minutes)

High-pressure pump flow

3.6 3.8 GPM

Diesel engine throttle

controls the flow. See

Figure 2.

Reverse osmosis module

Up to 1200 psi

Never exceed 1200 psi

pressure

Differential pressure (RO)

Not more than 1200 psi

See Figure 3.

Product water flow meter

2.1 GPM for freshwater,

See Figure 4. If source

1.25 GPM for seawater

water TDS is higher than

45,000, production of

water can or will be below

1.25 gpm.

Product water quality

Less than 1000 ppm

See WP 0017 00 if source

(TDS) and at least 2 ppm

water is higher than

chlorine

45,000 ppm

Stroke and speed controls

30% speed 60% stroke

See Figure 4 speed and

on chemical injection

stroke can be adjusted to

pump.

meet injection needs.

Air Tank Pressure

Above 30 psi.

Refill if less.

Diesel engine fuel (TQG

Check fuel level for both

Refill if necessary

and high pressure pump

engines