TM 10-4610-310-14

0029 00

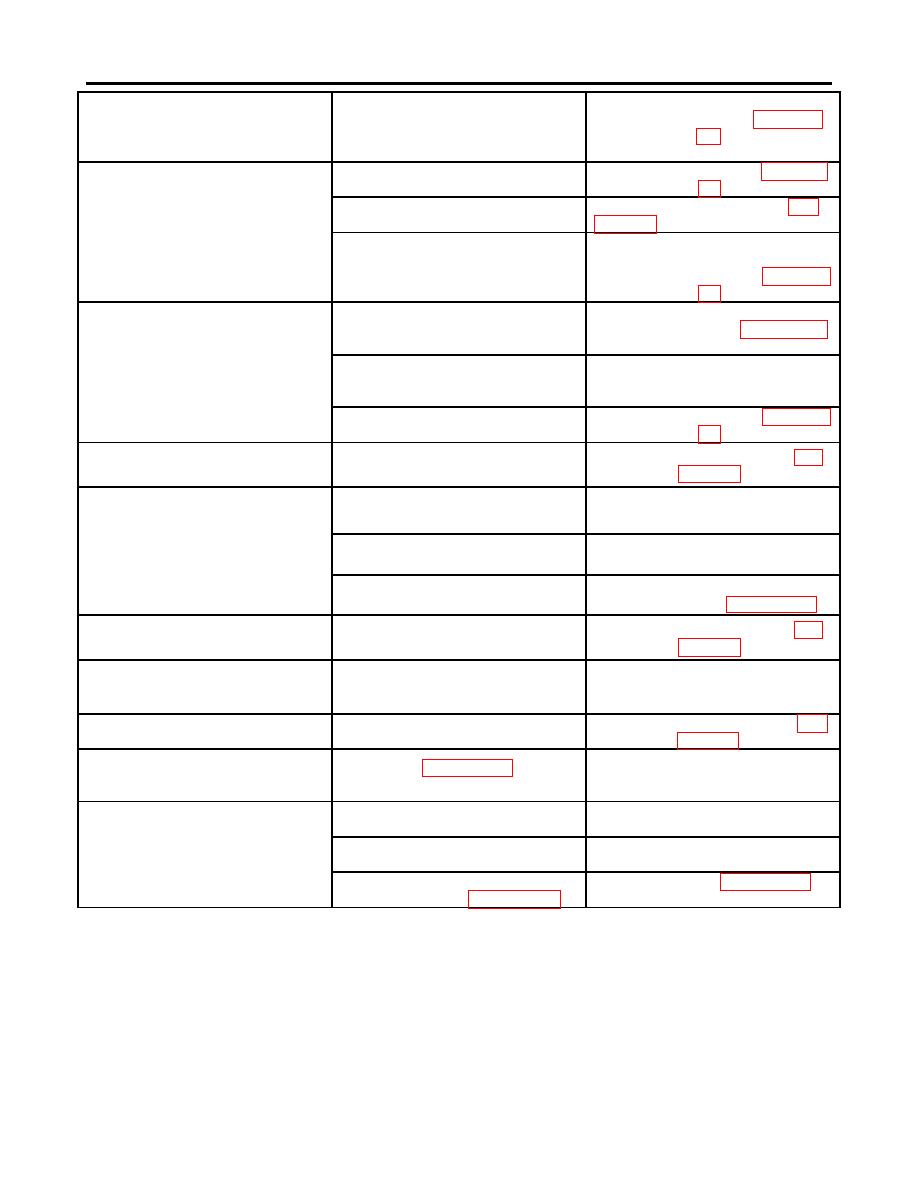

Inspect the recoil starter for loose

mounting bolts. Pull the starter rope

Replace recoil starter. (WP 0100

3. Binding recoil starter

back and forth to check for general

operation.

Fill with oil if necessary (WP 0094

Inspect engine oil level

Inspect the muffler for corrosion or

Replace damaged muffler (WP

damage

4. Excessive engine noise.

Tighten nuts. If damaged, remove

and replace vibration mounts.

Inspect vibration mounts

Notify unit maintenance. (WP 0094

Inspect for proper oil level in the HP

Fill HP pump with oil (WP 0041 00)

pump

5. Unusual gear box noise

Tighten connections

Inspect for loose mounting screws

Notify unit maintenance. (WP 0098

Inspect the gear box for damage

6. High-pressure pump leaks

Inspect the high-pressure pump for

Notify DS/GS maintenance. (WP

(water)

damage, corrosion or worn seals.

Inspect the breather vent on top of

Apply thread tape and hand tighten

the pump for looseness or damage

breather vent.

Inspect drain plug for looseness or

7. High-pressure pump leaks (oil)

Tighten drain plug

damage

Ensure the pump is not overfilled

Fill with oil to the center of the dot

with oil

on the sight glass (WP 0041 00)

8. High-pressure pump not building

Inspect the high-pressure pump for

Notify DS/GS maintenance. (WP

up pressure

damage, corrosion or worn seals.

Follow the procedures in step 1 and

Follow the procedures in step 1

9. Engine shuts down undirected

step 2.

and step 2.

10. Noise and vibration in the

Pulsation dampener

Replace pulsation dampener (WP

piping

unserviceable?

Ensure all scheduled maintenances

Check WP 0037 00 for

are completed as required. Notify

11. Engine low rpm

maintenance intervals

unit maintenance.

Inspect kinks or blockage in hose

Remove the blockage

and connection

Inspect reject valve for over

12. Blown rupture disc

Open the reject valve

tightening

Inspect High-pressure switch (notify

Replace if faulty (WP 0096 00).

unit maintenance WP 0067 00)

Notify unit maintenance.

END OF WORK PACKAGE

0029 00-2