TM 10-4610-310-14

OPERATOR MAINTENANCE

LIGHTWEIGHT WATER PURIFIER

TROUBLESHOOTING PROCEDURES

CHEMICAL INJECTION PUMP

GENERAL

The table lists the common malfunctions that you may find during the operation or maintenance of the

Lightweight Water Purifier (LWP) chemical injection electronic metering pump assembly or its components. You

should perform the tests/inspections and corrective actions in the order listed.

This manual cannot list all malfunctions that may occur, nor all tests or inspections and corrective actions. If a

malfunction is not listed or is not corrected by listed corrective actions, notify your supervisor.

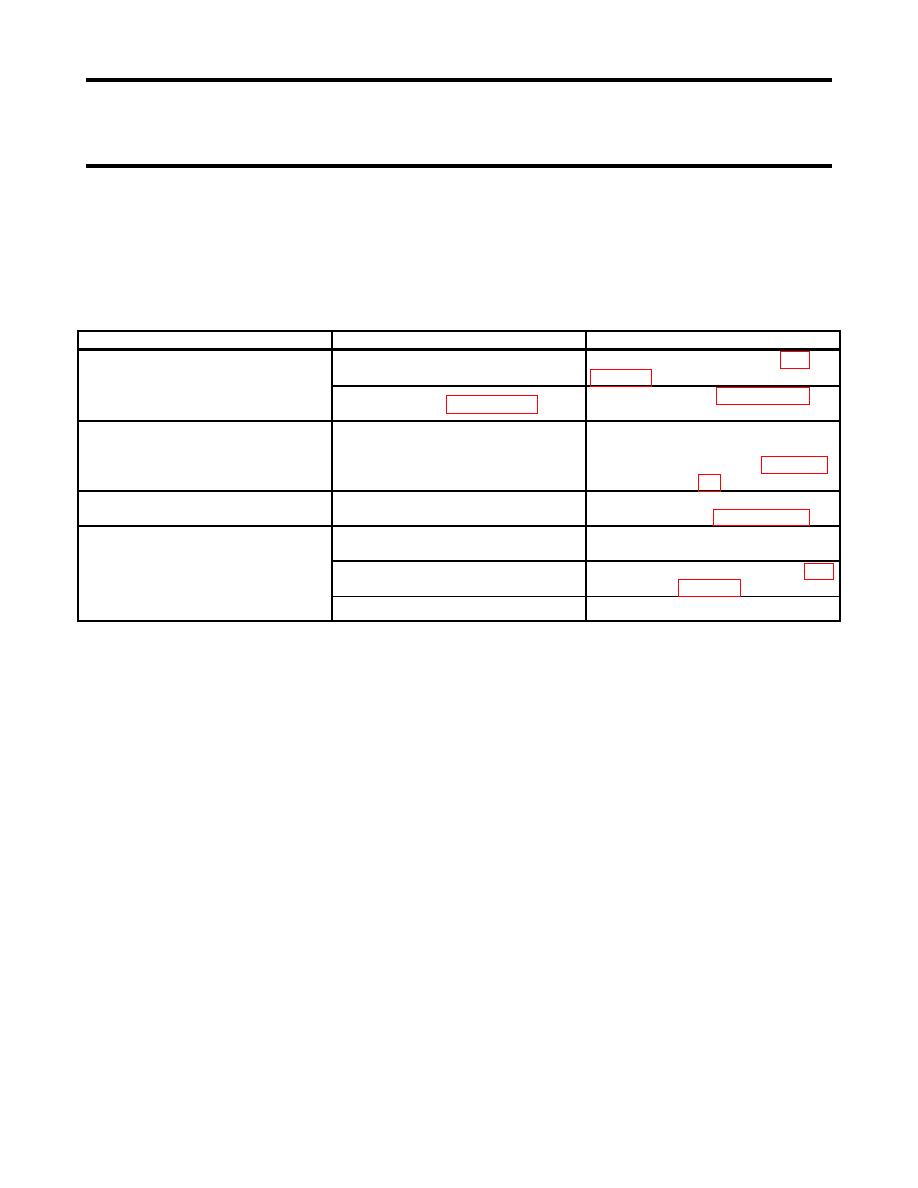

MALFUNCTION

TEST / INSPECTION

CORRECTIVE ACTION

Check for power to the control

If power is not available see WP

1. Chemical pumps are not running

module

- pilot light is off

Replace light bulb (WP 0102 00).

Test pump light (WP 0046 00).

Notify unit maintenance

Ensure that the RO pressure is

above 160 psi. If problem persists

2. Antiscalant pump and coagulant

Check low-pressure switch

pump are not running

notify unit maintenance (WP 0096

3. Chemical pumps are not running

Inspect the speed and stroke

Adjust the speed and stroke if

- pilot light is on

settings

necessary. See WP 0010 00.

Prime chemical pumps (see the

Lost prime

following section)

4. Chemical pump is running but no

Loose or broken connections or

Repair connections and tubing (WP

flow

tubing

Inspect chemical tanks

Refill if necessary

END OF WORK PACKAGE

0034 00-1 / 2 blank