TM 10-4610-310-14

UNIT MAINTENANCE

LIGHTWEIGHT WATER PURIFIER

TROUBLESHOOTING PROCEDURES

ULTRAFILTRATION MODULE

MODULE CABLE

General

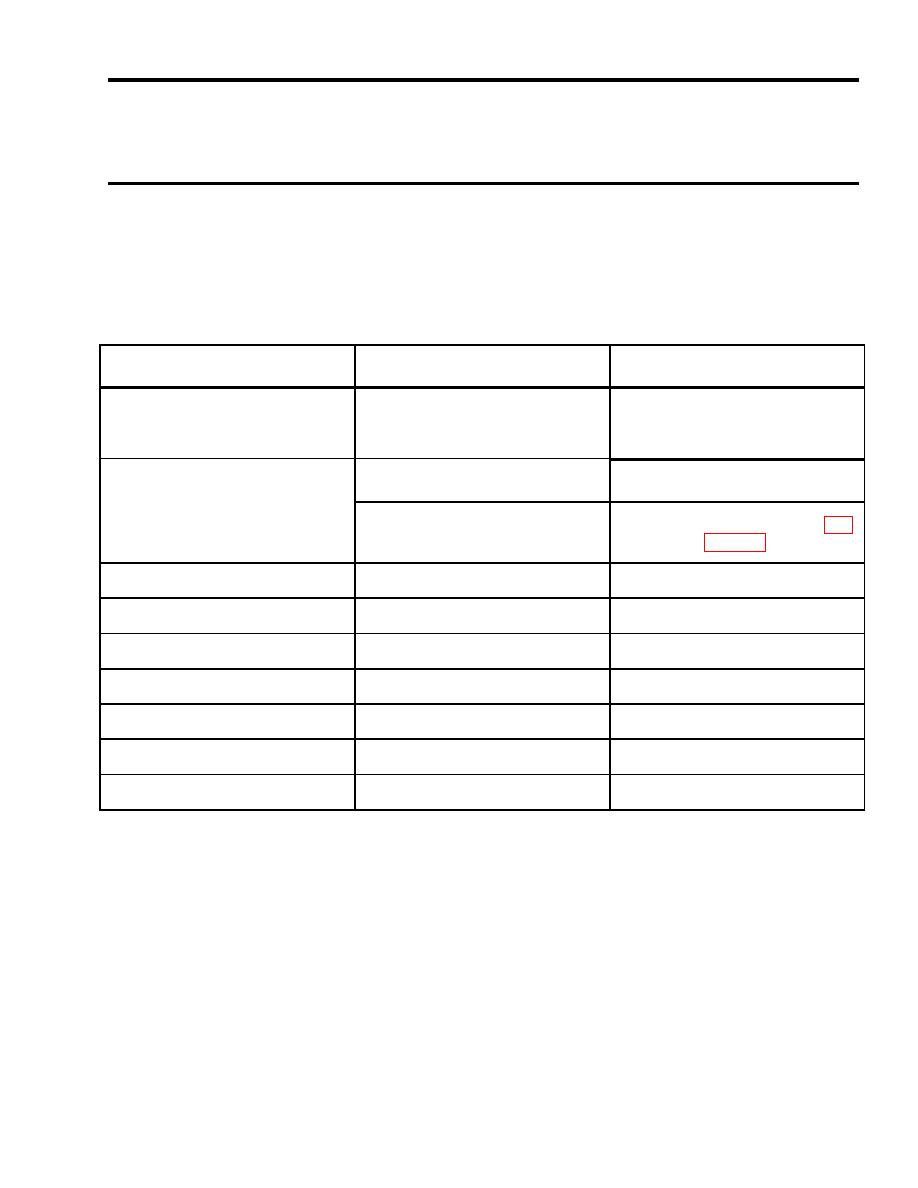

The table lists the common malfunctions that you may find due to faults in the module cable of the ultrafiltration

module. You should perform the tests/inspections and corrective actions in the order listed.

This manual cannot list all malfunctions that may occur, nor all tests or inspections and corrective actions. If a

malfunction is not listed or is not corrected by listed corrective actions, notify your supervisor.

MALFUNCTION

TEST / INSPECTION

CORRECTIVE ACTION

Inspect ground connection inside

the UF junction box for loose

Tighten any loose connections.

1. No power

connection. Inspect all the wire and

cable connections for looseness.

Measure continuity from pin A to

Replace cable if continuity is not

wire 2 and pin B to wire 4.

present.

2. Level Switch Malfunction

When the level is full, 120 VAC

Troubleshoot low-level switch. WP

should be present across wire 4

and 3.

Measure continuity from pin C to

Replace cable if continuity is not

3. Solenoid Valve V2A malfunction

wire 30 and pin J to wire 3.

present.

Measure continuity from pin E to

Replace cable if continuity is not

4. Solenoid Valve V2B malfunction

wire 32 and pin J to wire 3.

present.

Measure continuity from pin G to

Replace cable if continuity is not

5. Solenoid Valve V2C malfunction

wire 34 and pin J to wire 3.

present.

Measure continuity from pin D to

Replace cable if continuity is not

6. Solenoid Valve V3A malfunction

wire 31 and pin J to wire 3.

present.

Measure continuity from pin F to

Replace cable if continuity is not

7. Solenoid Valve V3B malfunction

wire 33 and pin J to wire 3.

present.

Measure continuity from pin H to

Replace cable if continuity is not

8. Solenoid Valve V3C malfunction

wire 35 and pin J to wire 3.

present.

Measure continuity from pin I to

Replace cable if continuity is not

9. Solenoid Valve V7 malfunction

wire 36 and pin J to wire 3.

present.

END OF WORK PACKAGE

0063 00-1 / 2 blank