TM 10-4610-310-14

UNIT MAINTENANCE

LIGHTWEIGHT WATER PURIFIER

TROUBLESHOOTING PROCEDURES

CONTROL MODULE

INTIAL SETUP

Equipment Condition Required

All equipment de-energized

Control Module

The table lists the common malfunctions that you may find during the operation or maintenance of the control

module and its components used in the Lightweight Water Purifier (LWP). You should perform the

tests/inspections and corrective actions in the order listed.

This manual cannot list all malfunctions that may occur, nor all tests or inspections and corrective actions. If a

malfunction is not listed or is not corrected by listed corrective actions, notify your supervisor.

WARNING

When checking for voltage on an energized component, extreme care must be taken. Only qualified and

authorized electrician should maintain, troubleshoot, and operate energized equipment. Injury or death to

personnel may result.

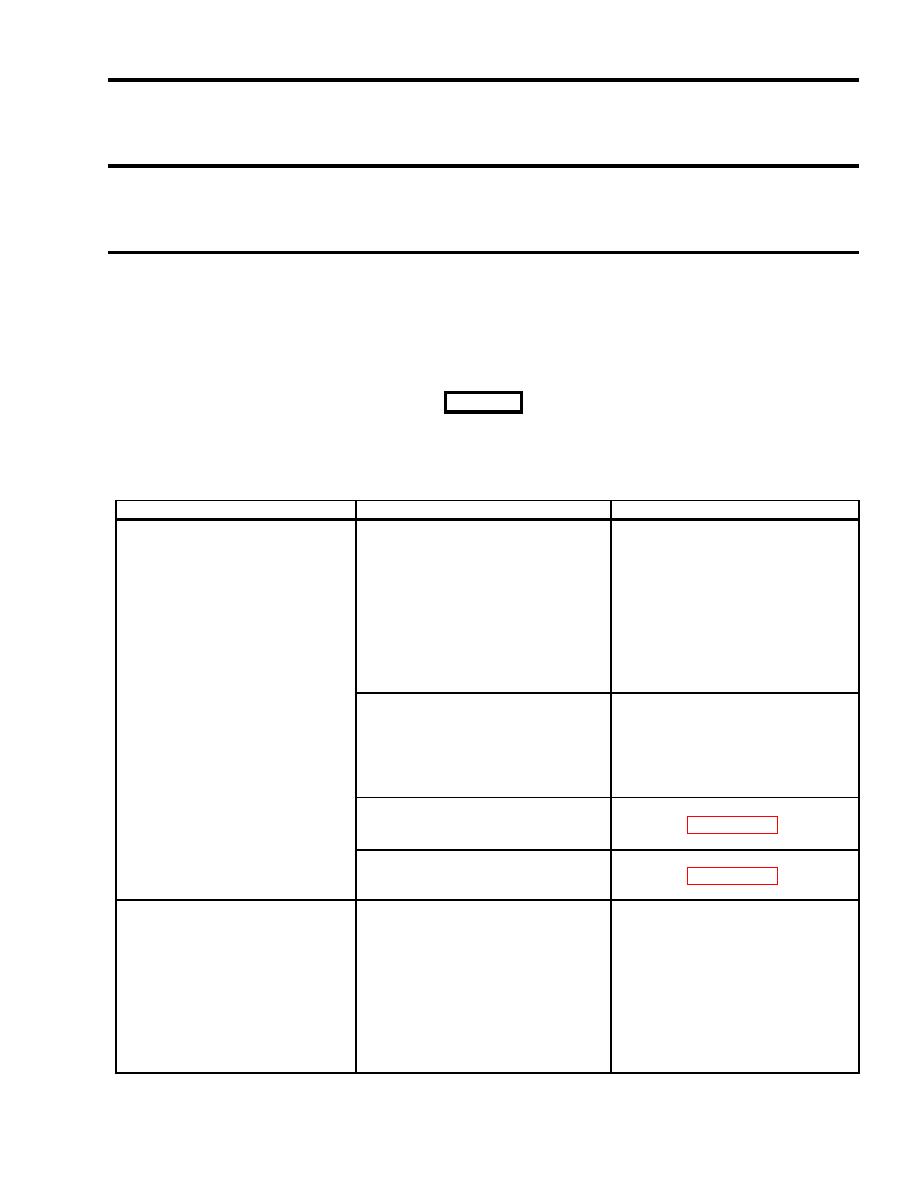

MALFUNCTION

TEST / INSPECTION

CORRECTIVE ACTION

Check connections of wire 36 from

output 7 of the PLC output card 1 to

valve V7. Check for continuity of

wire 36 from the PLC output card 1

Tighten any loose connections.

to valve V7. Wire 36 is Pin I on

Repair and replace any broken or

cable 6 between the control module

burnt wires. Replace if continuity

and the UF module and is the black

doesn't exists in the wire.

wire with a green stripe in the UF

module junction box.

1. UF filtrate tank is not filling up

Check connection and continuity of

(solenoid valve V7 malfunction)

Tighten any loose connections.

wire 3 on valve V7. Wire 3 is Pin J

Repair and replace any broken or

on cable 6 between the control

module and the UF module and is

burnt wires. Replace if continuity

doesn't exists in the wire.

the black wire with an orange stripe

in the UF module junction box.

Check surge protector (SP19) fault

light

Check PLC.

With power off,

Check connections of wire 22 on

output 0 of the PLC from the PLC to

Tighten any loose connections.

2. Air shutoff solenoid valve

the control relay (CR2), and check

Repair and replace any broken or

(SV1)

for continuity of wire number 22

burnt wires. Replace if continuity

from the PLC to the control relay.

doesn't exists in the wire.

0068 00-1