TM 10-4610-310-14

0068 00

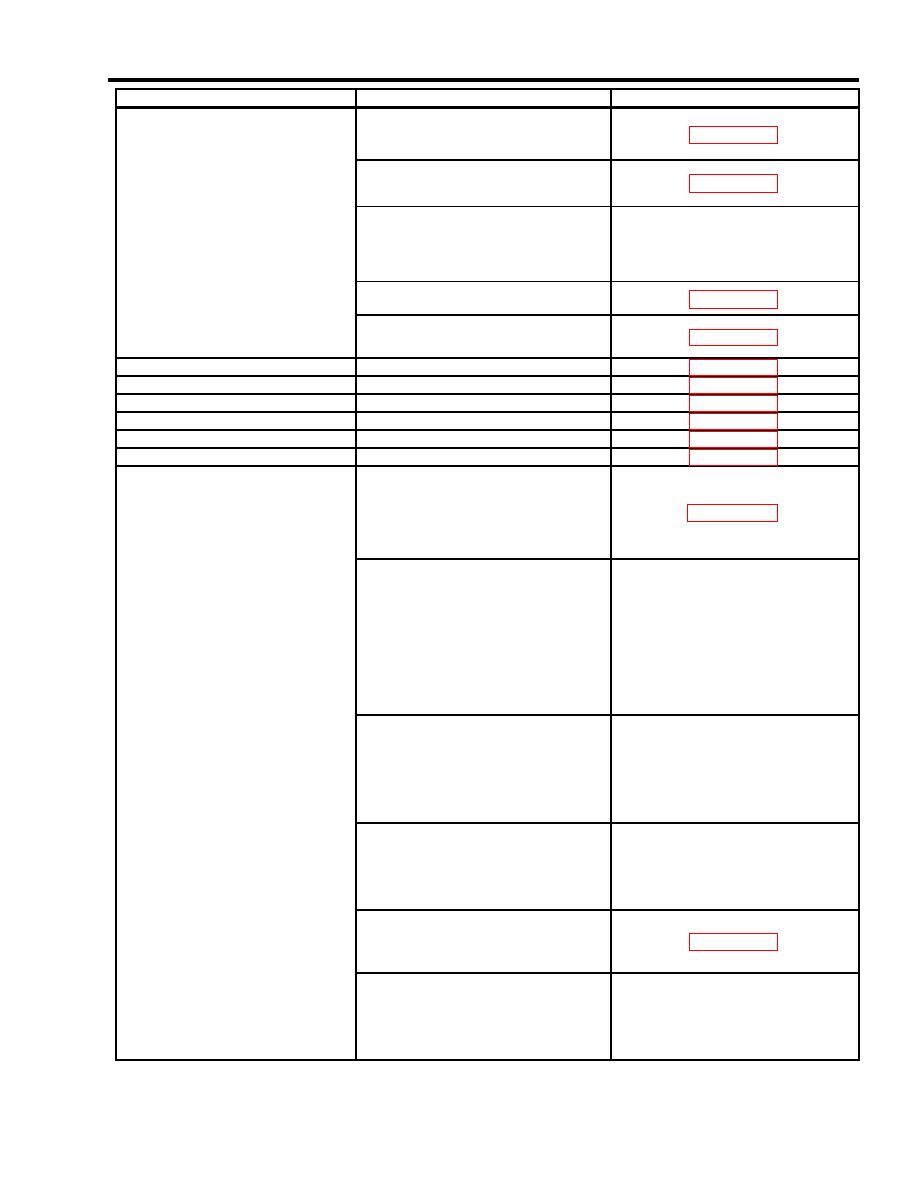

MALFUNCTION

TEST / INSPECTION

CORRECTIVE ACTION

Check surge protector (SP14) fault

light to see if it is on.

Check surge protector (SP21) fault

light to see if it is on.

Tighten any loose connections.

Check for continuity between the

Repair and replace any broken or

wire 18 and the PLC input 14.

burnt wires. Replace if continuity

doesn't exists in the wire.

3. Backwash Cycle components -

continued

Check PLC

Check high-pressure shutdown

switch

4. Backwash down 1st UF vessel

Troubleshoot solenoid valve V3A

5. Backwash down 2nd UF vessel

Troubleshoot solenoid valve V3B

6. Backwash down 3rd UF vessel

Troubleshoot solenoid valve V3C

7. Backwash up 1st UF vessel

Troubleshoot solenoid valve V2A

8. Backwash up 2nd UF vessel

Troubleshoot solenoid valve V2B

9. Backwash up 3rd UF vessel

Troubleshoot solenoid valve V2C

Troubleshoot BOOSTER pump

switch (SW2).

Put switch (SW2) in auto position.

If input light 13 is energized on the

PLC wire 17 is OK. Else, check

Tighten any loose connections.

connections of wire 17 on input 13

Repair and replace any broken or

of the PLC from the PLC to the

burnt wires. Replace if continuity

booster pump switch, and check for

doesn't exists in the wire.

continuity from the PLC to the

switch.

With power off, check connections

Tighten any loose connections.

of wire 39 on output 11 of the PLC

from the PLC to the booster pump

Repair and replace any broken or

10. Fast flush cycle components

burnt wires. Replace if continuity

switch, and check for continuity

from the PLC to the switch.

doesn't exists in the wire.

With power off, check connections

Tighten any loose connections.

of wire 45 from the switch to the

Repair and replace any broken or

motor starter (M2), and check for

burnt wires. Replace if continuity

continuity from the switch to the

doesn't exists in the wire.

starter.

Check surge protector (SP14) fault

light to see if it is on.

Tighten any loose connections.

Check continuity of the wire 17

Repair and replace any broken or

between the switch (SW2) and

burnt wires. Replace if continuity

PLC.

doesn't exists in the wire.

0068 00-3