VARIABLE SPEED CONTROL

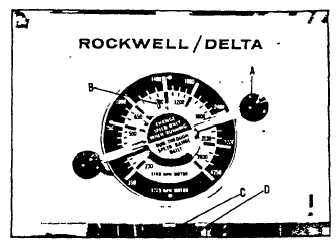

The pilot wheel (A) -Fig. 5, for Variable Speed Drive

should not be turned except when the motor is running,

to avoid putting unnecessary strain on the variable

speed drive belt and variable speed drive pulley

assembly. The pilot wheel is turned clockwise to make

the drill press run faster, and counterclockwise to slow it

down.

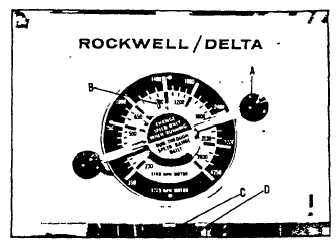

While changing speeds the pointer (B) Fig. 5, on the

speed dial will indicate the speed of the drill press.

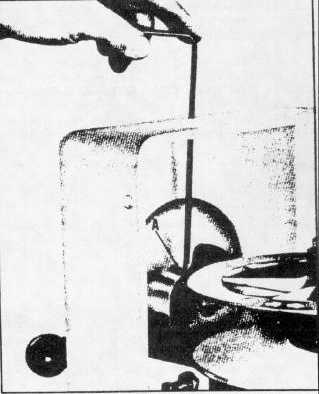

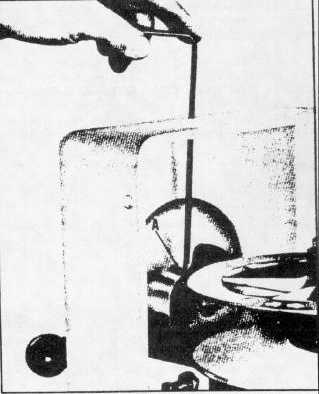

A drag plug or "dampener" is provided to restrict the free

rotation of the pilot wheel. The drag plug is properly

adjusted at the factory so that the drill press will hold a

constant speed and will not change speeds even on long

production runs, but still the pilot wheel can be turned

manually to change speeds as desired. If it ever

becomes necessary to change the adjustment, use a

long allen wrench and insert it down through the hole

located in the top of the guard, as shown in Fig. 6. Turn

the set screw (A) Fig. 6, clockwise to increase or

counter-clockwise to decrease the "dampener" pressure

on the pilot wheel.

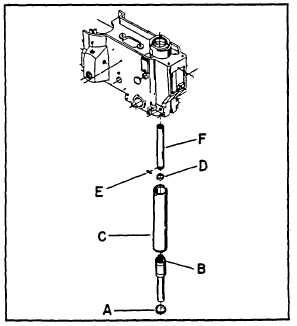

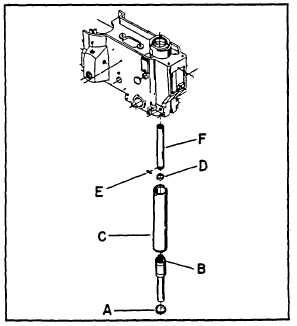

CHANGING LOWER SPINDLE ASSEMBLY

To replace the lower spindle assembly or to change drill

presses fitted with #2 Morse Taper Spindle to 1/2"

capacity key chuck spindle assembly, proceed as

follows:

1.

Lower the table to allow sufficient space between

the table and head to remove the spindle.

Fig. 7

Fig. 5

Fig. 6

2.

Lower quill approximately 2" to 4" and lock quill

locking nut

3.

Using a spanner wrench remove bearing closure nut

(A), and pull lower spindle (B) out of quill (C) Fig. 7.

4.

Remove garter spring (D), and key (E), Fig. 7.

Disengage sleeve (F) from spindle.

5.

Reassemble in reverse order.

5