INSTALLING MOTOR AND BELT

NOTE: When installing a Rockwell 8½" Frame Motor,

the No. 41-964 motor pulley that comes with the drill

press is used, as this pulley fits the V" shaft of the

motor. When a NEMA 182 frame motor is used, the

accessory motor pulley, number 41-965 with 7/8"

bore must be purchased.

1.

Insert the key in the keyway of the motor shaft and

place the pulley on the motor shaft until the edge of the

pulley sleeve is against the shoulder of the motor shaft.

2.

Make sure the key is in place and tighten the, two

set screws against the motor shaft.

3.

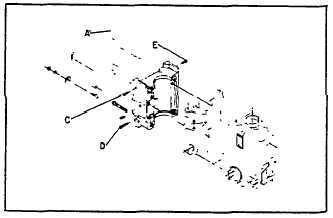

Mount the motor to the motor plate, (A) Fig. 13,

using the four 5/16" - 18 x 1" carriage bolts, the speed

nuts, the plain washers and the four 5/16" - 18 hex nuts.

Tighten the hex nuts only finger tight.

4.

Loosen the two screws (C and D) Fig. 13, and also

loosen the screw (E) on the right hand side of the head.

Set the motor plate 7/8" from the back of the drill press

head casting and tighten the three screws.

5.

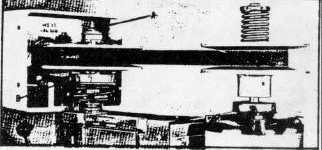

Loosen nut (A) Fig. 14. Then turn the pilot wheel

until the pointer (B) Fig. 15, is set to the lowest speed.

(350 rpm if a 1750 rpm motor is being used, or 230 rpm

if an 1140 rpm motor is being used.) Now tighten nut (A)

Fig. 14, just enough so that it adjusts the top half of the

spindle pulley downward, until it just touches the lower

pulley half. NOTE: This adjustment is made with the belt

off.

6.

Turn the pilot wheel until the pointer (B) Fig. 15, is

set to the highest speed.

7.

With a crow bar, raise the front end of the bracket

(B) Fig. 14, in order to separate the two halves of the

spindle pulley as far as possible. Put the belt on the

spindle pulley, jerking it into the pulley to keep the two

halves wedged apart, and remove the crowbar.

8.

Work the belt onto the motor pulley with one hand,

while rotating the spindle pulley with the other hand.

9.

It is important that the motor shaft is parallel with the

drill press spindle. Place a spirit level in a left to right

position, first on the spindle pulley and then on the motor

pulley. The bubble should be in the same relative

position when testing the motor pulley as when testing

the spindle pulley. If an adjustment is necessary, adjust

the motor on the motor plate, until the motor shaft and

drill press spindle are parallel.

10. Then place the level in front to back position first on

the spindle pulley and then on the motor pulley. (Make a

mental note of the position of the bubble.) If the motor

pulley has to be tilted to the front or rear, loosen the

three screws (C, D, E) Fig. 13, and using a crowbar pry

out the top or bottom of the motor plate until the motor

shaft is in parallel alignment with the drill press spindle.

Then tighten the three screws (C, D, E) Fig. 13.

Fig. 13

Fig. 14

11. Place the spirit level on the belt midway between the

pulleys. If the bubble appears the same as in step 10,

the height of the motor pulley is correct.

12. If necessary, adjust the height of the motor pulley on

the shaft of the motor. (In some cases, the height of the

motor on the motor plate must be changed,. If this is

done, repeat steps 9 and 11.)

13. Tighten the four 5/16" - 18 hex nuts mentioned in

step 3.

8