HOW TO CHANGE SPINDLE ADAPTERS

One of the unique features of 17" Key Chuck Drill

Presses is that they come equipped with a lower spindle

assembly having a 1 1/16" - 20 thread (A) Fig. 10, and

the Cat. No. 15-830 Drill chuck which has a threaded

mounting collar (B) Fig. 10. Various spindle adapters,

shown in Fig. 11, can also be adapted to the threaded

spindle of your 17" key chuck Drill Press. These

adapters are available as an accessory.

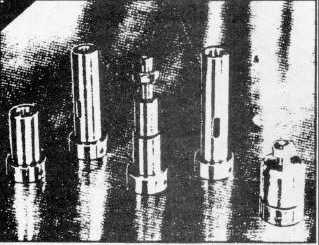

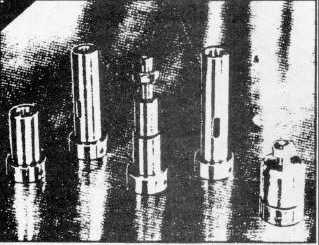

The spindle adapters, shown in Fig. 11, along with the

Cat. No. 15-830 Drill Chuck, shown in Fig. 10, can be

used on 17" Morse Taper Drill Presses when the lower

spindle cartridge (Part No. 402-07-301-5001 is installed

in the drill press instead of the standard #2 Morse Taper

Spindle Cartridge.

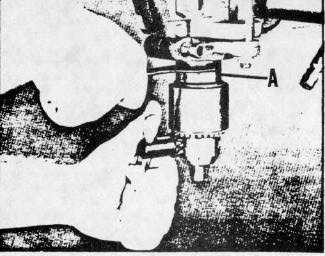

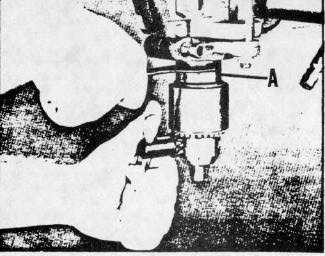

When removing either the chuck or the spindle adapters,

we recommend the use of the Cat. No. 15838 spanner

wrench which is supplied with Key Chuck Drill Presses.

Turn the locking collar of the adapter or chuck with the

spanner wrench while keeping the spindle from turning

by either holding belt or holding the chuck with the-chuck

key in one of the pilot holes in the nose of the chuck, as

shown in Fig. 12.

When attaching adapters to the spindle, it is very

important to wipe clean both the spindle taper and taper

hole in adapter. Then place the adapter on the spindle

and tighten the locking collar (A) Fig. 12.

If in checking the spindle for accuracy, there should be a

run out, we suggest that the adapter be removed and

turned perhaps one quarter or one-half turn and

replaced. This may reduce or eliminate the run out, it

may also increase it, in which case, remove the adapter

and turn it some more on the spindle.

LUBRICATION

The

quill

and

pinion

gear

should

be

lubricated

occasionally with medium oil in the oil hole provided on

the right hand side of the drill press head.

The spindle return clock spring should be oiled twice a

year using light machine oil.

The raising mechanism support collar should be

lubricated with medium oil applied to periphery of the

column.

The spindle splines should be lubricated every three

months with SAE-140 Gear Oil.

NOTE: The bearings of Rockwell motors are grease

sealed for life and need no further lubrication. DO

NOT USE OIL ON MOTOR.

Fig. 10

Fig. 11

Fig. 12

7