remove drive link

9.

Remove drive link (8) and inspect

it for cracks and for chipped or

damaged splines. No perceptible

lash (play) should be noted

between mating spline parts.

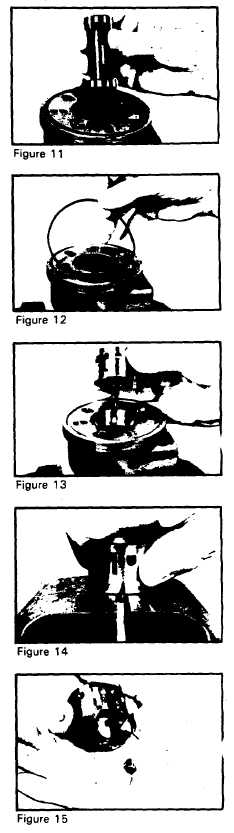

Replace, if necessary SEE FIGURE

11.

remove & discard

10.

Remove seal ring (5) from housing

seal ring

(15) seal ring groove and discard

seal ring. SEE FIGURE 12.

remove & inspect

11.

Remove commutator (9) which is

commutator

a close slip fit into housing (15),

by inserting two fingers into its

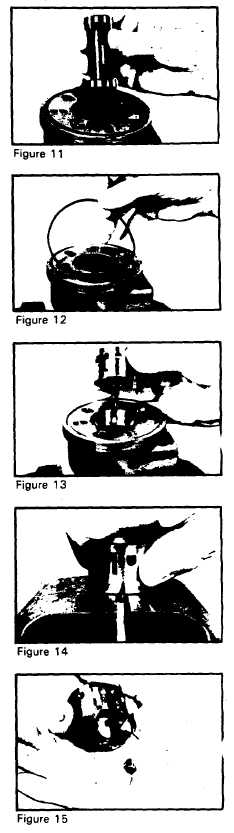

center cavity and lifting. SEE

FIGURE 13. The commutator drive

pin (10) will probably be in the

commutator when the

commutator is removed. Inspect

the commutator for nicks, burrs,

or brinelling on the outside

diameter surface. Inspect for

broken edges on the commutation

slots. Inspect the exposed area of

the drive pin slot for extreme

wear or damage. Only the

commutator drive pin can be

serviced separately. A worn or

damaged commutator will require

a new matched housing and

commutator service assembly set.

remove

12.

Remove commutator drive pin

commutator drive

(10) only if it must be replaced. If

pin

the pin does not readily pull out of

the commutator, clamp the

exposed portion of the drive pin in

a vise and twist the commutator

from the drive pin by hand only.

SEE FIGURES 14 and 15.

11