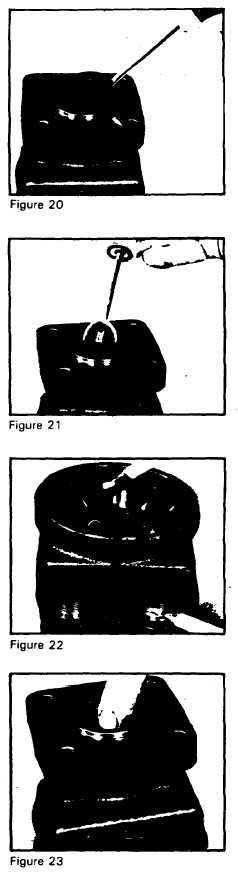

remove seals

16.

Remove housing (15) from vise

and place it on a clean flat work

surface with wearplate end down.

Pry out and discard the dirt and

water seal (20) and inner seal (16)

using a dull-edged screw driver.

Be careful not to gouge or nick

other components during the pro-

cess. SEE FIGURE 20 and 21.

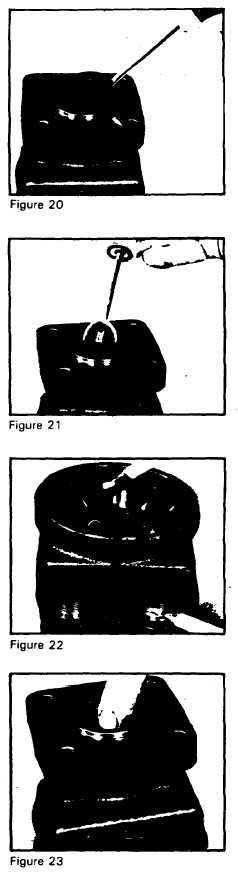

inspect housing

17.

Inspect the housing (15) assembly

assembly

for cracks, the housing machined

surfaces for nicks, burrs, brinelling

or corrosion. Remove burrs that

can be removed without changing

dimensional characteristics.

Inspect the tapped holes for

thread damage. SEE FIGURE 22. If

the housing is defective in these

areas, discard the housing (15)

assembly and commutator (9)

assembly and the disassembly of

the MAF TorqmotorTM is

completed. If the housing

assembly passed inspection to

this point, continue the inspec-

tions per Step 18.

inspect housing

18.

Inspect the outer bearing (19), the

bearings, thrust

inner bearing (12), the thrust

washers & backup

bearing (14), thrust washers (13),

washer

and back-up washer (17), while

assembled in the housing (15).

The bearing rollers should be

firmly retained in the bearing

cages, but must turn and revolve

freely. The full complement of

bearing rollers and the thrust

washers must be free of brinelling

and corrosion. Seal back-up

washer must be free of cracks,

chipped edges or burrs. SEE

FIGURE 23. If the housing

assembly passed this inspection,

and the inspections in Step 13

and 17, the disassembly of the

MAF TorqmotorTM is completed.

If only the bearings, thrust

washers, or back-up washer show

deterioration, they can be

replaced. Go to the next step.

13