MAF Assembly

Replace all seals and seal rings with new ones each time you

reassemble the MAF unit. Lubricate all seals and seal rings with

SAE 10W40 oil or clean grease before assembly.

NOTE: Individual seals and seal rings as well as a complete seal kit

are available. SEE FIGURE 29. The parts should be available

through most OEM parts distributors or Ross approved MAF

distributors. (Contact your local dealer for availability).

NOTE: Unless otherwise indicated, do not oil or grease parts before

assembly.

Wash all parts in clean petroleum-based solvents before assembly.

Blow them dry with compressed air. Remove any paint chips from

mating surfaces of the end cover, stator, wearplate and housing and

from port and sealing areas.

WARNING

WARNING: SINCE THEY ARE

FLAMMABLE BE EXTREMELY

CAREFUL WHEN USING ANY

SOLVENT. EVEN A SMALL EX-

PLOSION OR FIRE COULD CAUSE

INJURY OR DEATH.

WARNING

WARNING: WEAR EYE PROTEC-

TION AND BE SURE TO COMPLY

WITH OSHA OR OTHER

MAXIMUM AIR PRESSURE

REQUIREMENTS.

service housing

1.

If a service housing and

and commutator

commutator assembly set has

replacement

been procured for the MAF unit

being serviced, the housing com-

ponents are already installed. Start

the assembly procedure with Step

9.

housing seal

2.

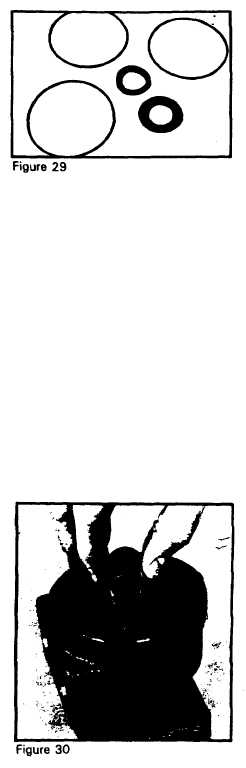

If the housing assembly (15) is

replacement only

being reused with original bearings

intact, place housing on a clean

work surface with the housing

wearplate surface up. Apply a

small amount of clean grease to a

new inner seal (16). Deform the

seal between two fingers and

insert the seal into the housing

seal cavity between the back-up

washer (17) and a thrust washer

(13). SEE FIGURE 30. The seal

must be properly seated and

against the back-up washer (17),

with the seal lip facing the thrust

washer (13). The back-up washer

(17) must be seated against the

retaining ring (18). Go directly to

assembly procedure #8.

NOTE

NOTE: You will probably have to

pick-up the housing and use

fingers through each end of the

housing to seat the seal into the

correct position.

15