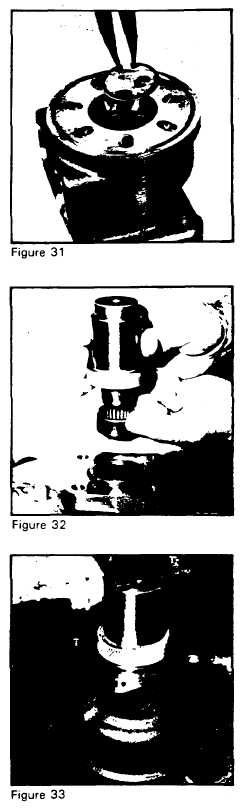

install retaining

3.

If the housing (15) has been com-

ring

pletely disassembled, place the

housing, mounting flange end

down, on a clean work surface.

Install retaining ring (18) into the

housing retaining ring groove. Be

sure the rounded edge of retaining

ring is facing in toward the larger

housing cavity. Use appropriate

retaining ring pliers. SEE FIGURE

31,

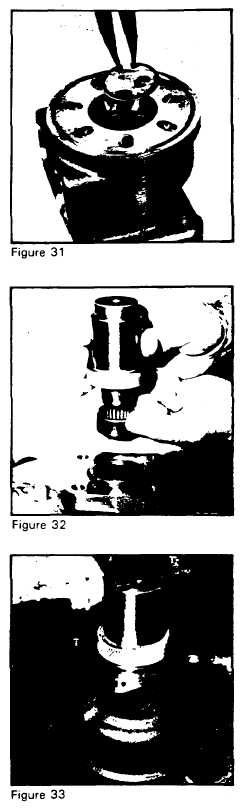

press in bearing

4.

Thoroughly grease the rolls of a

NEW bearing (19) with clean

wheel bearing. grease. Press the

bearing into housing (15) from the

mounting flange end of the

housing bore, using bearing

mandrel (special tool FIGURE 1,

Page 7A) against the lettered end

of the bearing shell. SEE FIGURES

32 and 33. Take care during this

procedure that the housing is

square with the press base and

that the bearing is not cocked. The

bearing mandrel will control the

bearing (19) press depth to the

required .135/.125 inches

(3.43/3.18 mm) from the flange

end of the housing.

NOTE:

NOTE: If the bearing mandrel

shown is not available, alternate

methods may be used to press in

the bearing but the bearing depth

location must be maintained.

CAUTION

CAUTION: The controlled press

depth of bearing (12) and (19)

into the housing is required to

ensure adequate bearing support,

and correct bearing relationship to

adjacent components when

assembled.

CAUTION

CAUTION: Because bearings (12)

and (19) have a press fit into the

housing, they must be discarded if

removed from the housing. They

must not be reused.

16