Engine

Disassembly and Assembly

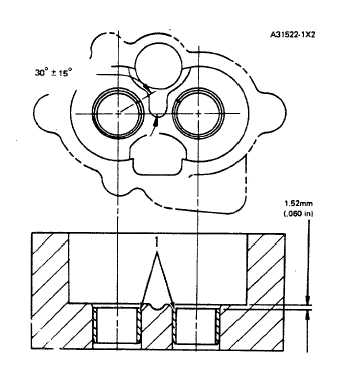

a.

Put bearings (1) in position on the inside of the

scavenge pump body assembly with the chamfer on the

bearing toward the outside of the pump body. Install the

bearing until it is 1.52 mm (.060 in.) below the inside

machined surface of the scavenge pump body assembly.

Make sure the joints in the bearings are at an angle of

30°+ 150 from the center line through the bores in the

scavenge pump body and toward the outlet passage of

the pump. The outlet passage has a cavity between the

bearing bores.

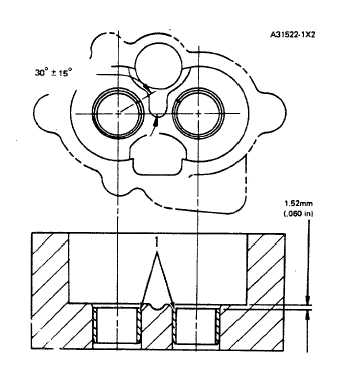

2. Install the bearings in oil pump body assembly with

tooling (A) and a press as follows:

a.

Put bearings (2) in position on the inside of the

oil pump body assembly with the chamfer on the

bearings toward the outside of the pump body. Install the

bearings until they are even with the outside of the pump

body.

Make sure the joints in the bearings are at an angle of

30° + 15° from the centerline through the bearing bores

and toward the outlet passage of the pump. The outlet

passage has a cavity between the bearing bores.

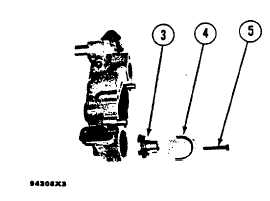

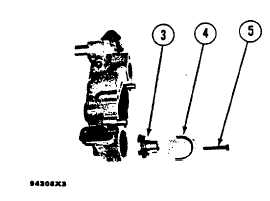

3.

Check the condition of the relief valve. Check the

condition and specifications for all the parts of the oil

pump before it is assembled. See Oil Pump in

Specifications.

4. Put clean engine oil on all the parts of the oil pump.

5.

Install pressure relief valve (3), cover (4) and bolt (5)

in the oil pump body assembly

137