TM 10-4610-310-14

0022 00

SECOND PASS SETUP AND OPERATING PROCEDURE - continued

7. Place the control module MODE switch to the MAINTENANCE position. (NOTE: When the LWP is

operating in the MAINTENANCE MODE the system will not backwash or fast flush. This will conserve the

first pass product water so that the daily water production is maximized. If the operator observes any

significant TMP increases (greater than 4 psid in 4 hrs) during second pass operation a manual backwash

or fast flush can be initiated. See WP 0040 00)

8. Energize the control module by placing CB1 to the ON position. Do not operate the raw water pump.

9. Start up LWP following the normal operating instructions in WP 0008 00 and 0009 00. Do not operate the

antiscalant chemical pump nor the raw water pump. Set the antiscalant pump speed to 0. Follow the

chemical injection instructions for the hypochlorite injection in WP 0010 00.

CAUTION

The water level in the settling tank must be constantly monitored. Shutdown operations when it is almost empty.

Damage to equipment may result.

10. Adjust the RO feed pressure with reject control valve V11 to a product water flow rate of 2.25 gpm. (NOTE:

During operation of the second pass, the product flow rate will always be adjusted to 2.25 gpm.)

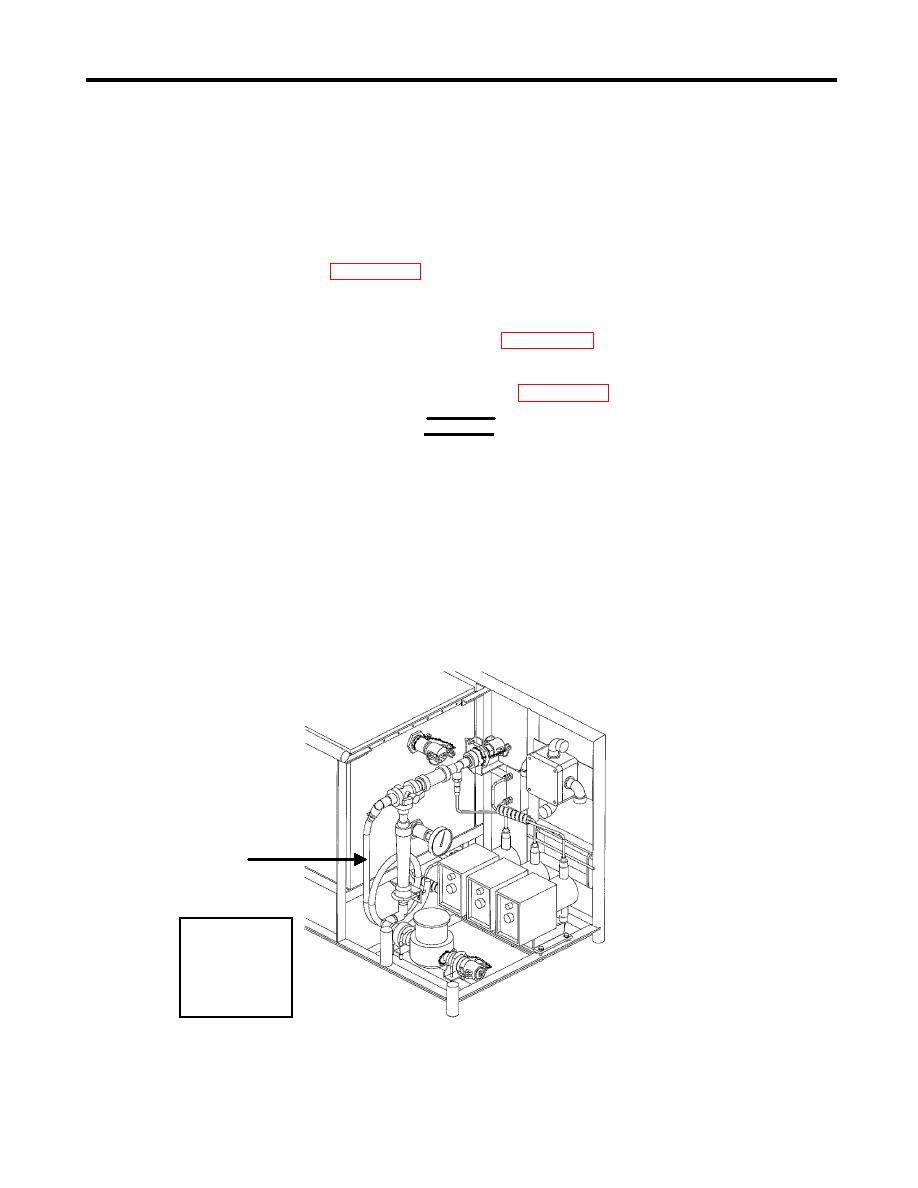

11. Measure the water quality of the second pass product water using the TDS and chlorine meters. The

product TDS should be less than 1 mg/liter in double pass mode after the NBC canisters at sampling hose.

See Figure 3.

SAMPLING HOSE

SOME

DETAILS

REMOVED FOR

CLARITY

Figure 3. Chemical Module Sampling Hose.