TM 10-4610-310-14

0022 00

PROCEDURE SUMMARY- continued

settling tank is completely filled with the first pass product water, the booster pump will be used to supply water

from the settling tank to the UF module. The UF module will be operated with the control panel MODE switch in

maintenance mode so that the system does not backwash and waste first pass product water. In addition, UF

reject will be returned to the settling tank inlet to conserve first pass product water. The hypochlorite pump will

be used to inject hypochlorite. The product water tank T3 will be used for storage of the second pass product

after the NBC filter and chlorine injection.

FIRST PASS SETUP AND OPERATING PROCEDURE

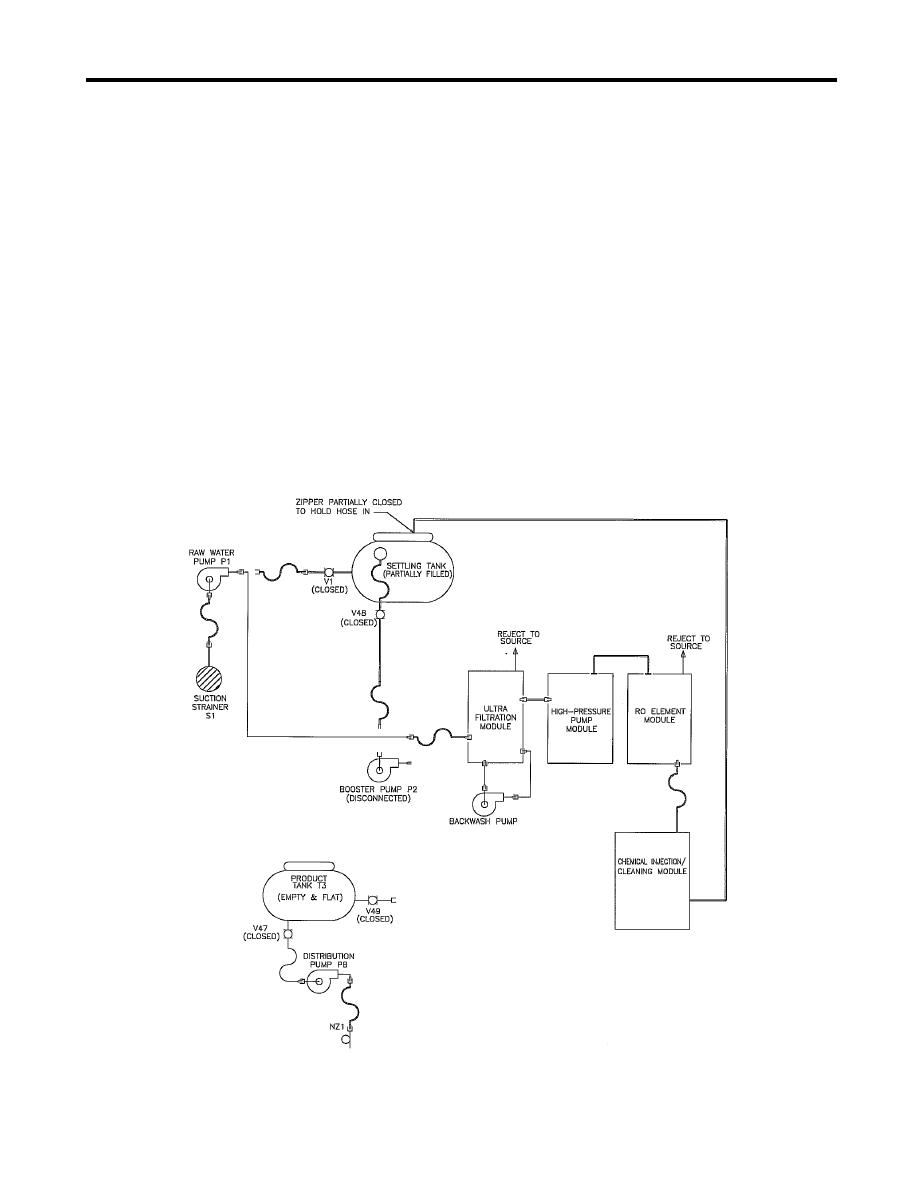

1. The procedure begins after the LWP has been shutdown and de-energized, the settling and product water

tanks drained, and the LWP configured in the normal operating mode. The settling tank must be located

close enough to the RO module so that it can be filled with product water. Refer to Figure 1 as a guide in

performing the procedures for setup and operation of the first pass. (NOTE: If the system has already

been operated in double pass mode, it will be necessary to disconnect and cap the NBC canisters from the

product hoses between the RO module and chemical injection/cleaning module.)

Figure 1. Layout for the First Pass.