TM 10-4610-310-14

0043 00

OPERATOR MAINTENANCE

LIGHTWEIGHT WATER PURIFIER

REVERSE OSMOSIS MEMBRANE

CLEANING

INITIAL SETUP

Materials/Parts

Special Environmental Conditions

High pH cleaner (item 10, WP 0136 00)

Do not allow drainage to contaminate source

Low pH cleaner (item 11, WP 0136 00)

Equipment Condition Required.

Tools

All equipment de-energized

Paddle, stirring, (PN 3485K14)

Water in product tank

Immersion heater, 2000-watt, (PN 2850332001)

Tool Kit (PN 3600486000)

Adapter, cleaning, (PN 2554647000)

Stop watch (table 2, item 49, WP 0135 00)

GENERAL

This work package contains information and instructions to clean the Reverse Osmosis (RO) membranes in the

RO module in the Lightweight Water Purifier (LWP). The cleaning process includes product flush, high pH

cleaning and low pH cleaning.

CLEANING PARAMETERS

Reverse osmosis membrane elements should be cleaned when:

The permeate flow decreases by 10% from the mission start

The salt content of the product water increases by 10% from the mission start

The differential pressure increases by 15% from the mission start

The system operating pressure reaches the limit set in Table 1.

NOTE

The following table is to be used as a supplemental guidance to determine the RO membrane cleaning

requirement. The product quality, production quantity, environmental effects and past performance

characteristic of the unit must also be taken into consideration. The unit must produce 2.1 gpm under 20,

000 ppm and 1.25 gpm at or above 20, 000 ppm source water. Product quality must always be less than

1000 ppm.

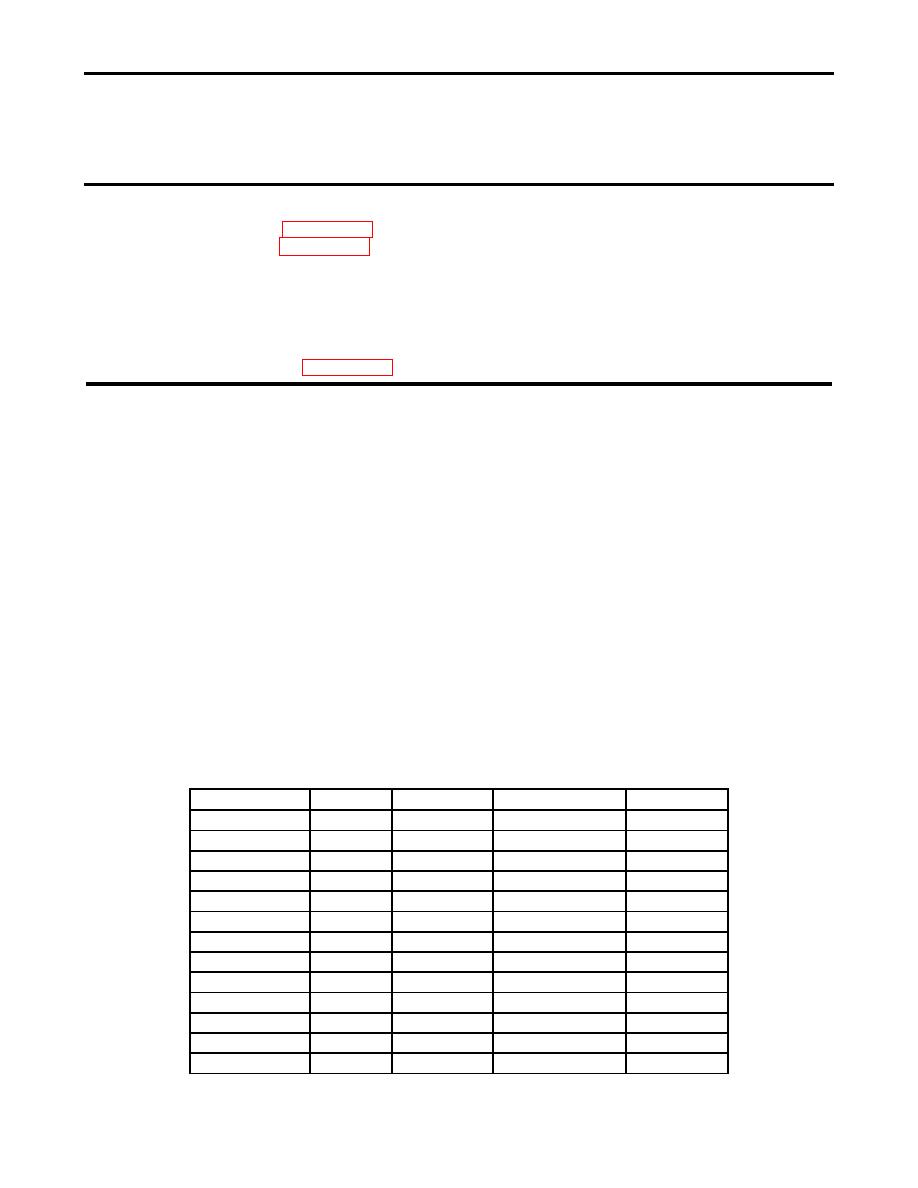

Table 1. Reverse Osmosis Cleaning Limit.

Feed (TDS)

Feed temp. Permeate flow Operating pressure

LIMIT

ppm

(F)

(gpm)

(psi)

(psi)

0-5,000

50-90

2.1

0-484

550

5,000-10,000

50-90

2.1

484-597

650

10,000-15,000

50-90

2.1

597-717

800

15,000-19,999

50-90

2.1

717-843

950

20,000 - 25,000

50-90

1.25

548-632

700

25,000 - 30,000

50-90

1.25

632-717

800

30,000 - 35,000

50-90

1.25

717-806

900

35,000 - 40,000

50-90

1.25

806-898

1000

40,000 - 45,000

50-90

1.25

898-996

1100

45,000 - 50,000

50-90

1.25

996-1100

1200

50,000 - 55,000

50-90

1.1-0.96

1100-1200

N/A

55,000 - 60,000

50-90

0.96

1200

N/A