TM 5-3800-205-10-2

ADVANCED MACHINE OPERATION AND JOB SITE MANAGEMENT

GUIDELINES - CONTINUED

0006 00

COMPACTION OPERATIONS - CONTINUED

c.

Proper moisture content in soil is crucial to achieve satisfactory compaction. Insufficient moisture causes soil to

break up during compaction or to not compact at all. Too much moisture results in soil deformation during com-

paction.

d.

Prior to compaction, determine moisture content of soil.

(1)

If moisture content is too high, either delay compaction until moisture has had a chance to evaporate or use

cultivator (WP 0024 00) to turn soil, in order to accelerate evaporation.

NOTE

Making several passes to discharge liquid solution is preferable to making one pass, where application is so

heavy that flooding of soil results.

(2)

If moisture content is too low, use a multi-pass procedure to gradually add moisture to soil. Distribute

water, in 2nd gear, at a low flow rate, with upper spray bar spray heads adjusted to in. height. Refer to

application rate charts at end of work package for further guidance.

e.

To achieve harder, longer-lasting compacted surfaces with a minimum of cure time, apply soil stabilizers using

pressure discharge from lower spray bar (WP 0005 00) prior to compaction.

2.

Compaction Operations.

a.

Fill tank to achieve maximum machine weight.

b.

Raise tank to travel height.

Drive in 1st gear in longitudinal direction of work surface.

c.

d.

Offset subsequent passes by width of one tire.

e.

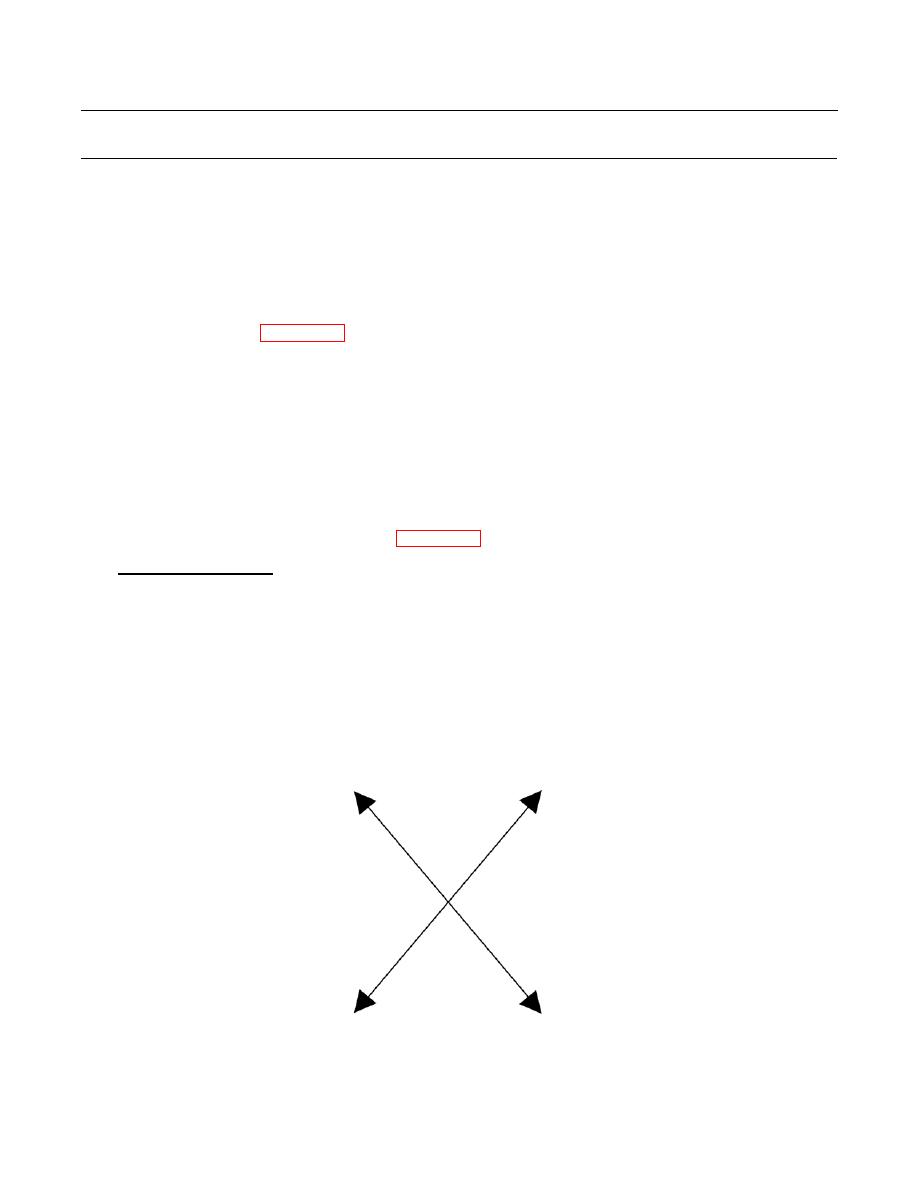

After longitudinal direction has been compacted, repeat operation at 45-degree angle to longitudinal direction.

f.

After compaction at 45-degree angle, repeat compaction at a cross pattern as shown below.

390-1709

g.

After compaction, cultivating may be required to break up and aerate soil.

0006 00-10