TM 5-3800-205-10-2

TROUBLESHOOTING PROCEDURES - CONTINUED

0011 00

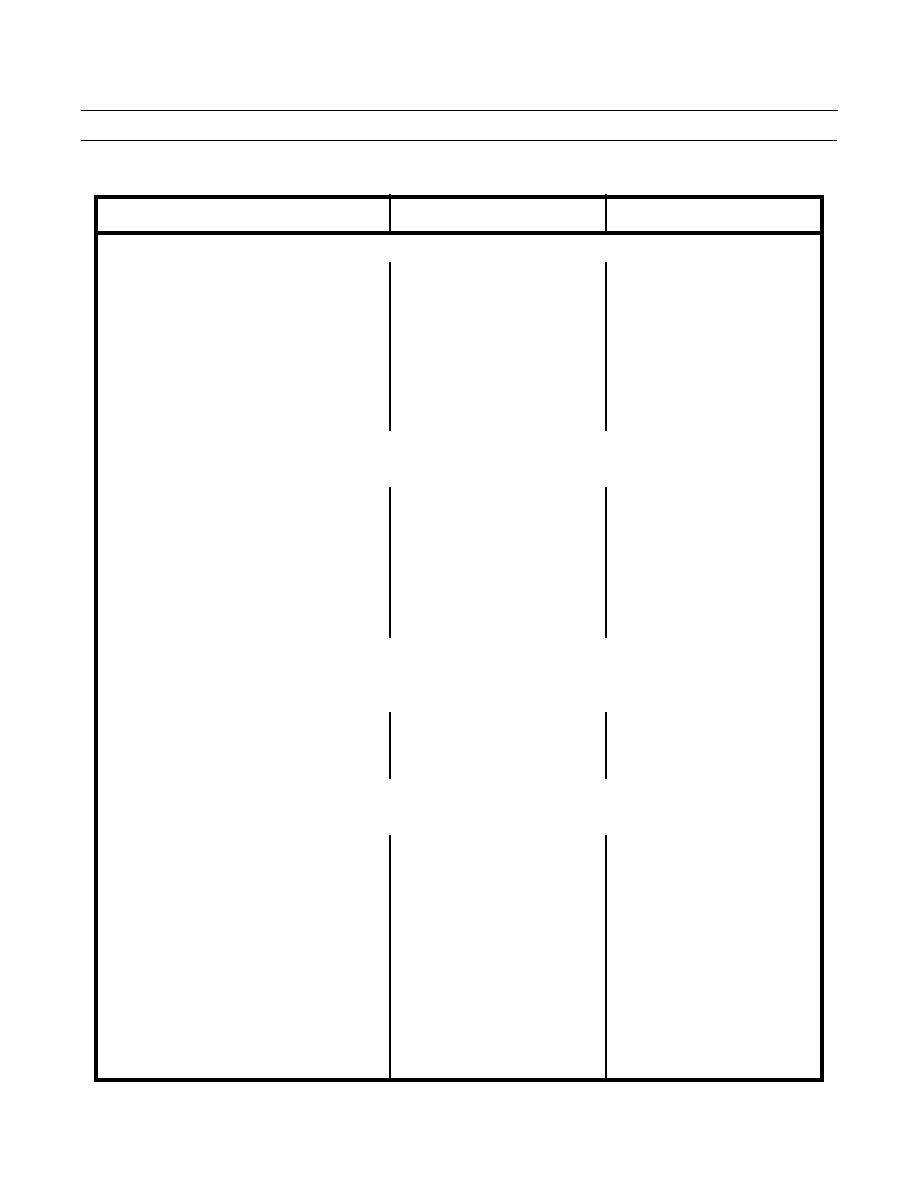

Table 1. Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ELECTRICAL SYSTEM - CONTINUED

3. If air pressure is less than 125

7.

Horn Will Not Sound When Button is

3. Check air pressure gage for an

psi (862 kPa), ensure air tank

Pressed - Continued.

indication of 125 psi (862

drain valve(s) are closed. If

kPa).

problem still exists, notify

Unit Maintenance.

8.

Headlight(s)/Parking Light(s) Do Not

Operate When SER. DRIVE or PARK

Functions are Selected.

NOTE

A thirty (30) minute cool down time may be required before circuit breaker automatically resets.

If circuit breaker does not

Check that circuit breaker is not

automatically reset, notify Unit

tripped at fuse/circuit breaker

Maintenance.

panel in cab.

1. Select STOP LIGHT or SER.

9.

High Beams Do Not Come On.

1. Ensure STOP LIGHT or SER.

DRIVE. If problem still exists,

DRIVE function has been

go to test step 2.

selected on military light

switch.

WARNING

Park machine on level ground, stop engine, and lower tank to prevent injury to operator and/or

severe damage to machine.

2. Check for mud and dirt around

2. Clean mud or dirt from high

high beam switch.

beam switch. If problem still

exists, go to test step 3.

NOTE

A thirty (30) minute cool down time may be required before circuit breaker automatically resets.

3. Check that circuit breaker is

3. If circuit breaker does not

not tripped.

automatically reset, notify

Unit Maintenance.

Reconnect connector, if required.

10. No Power at Water Distributor Control

Check connector of electrical

If problem still exists, notify Unit

Panel.

harness at receptacle connector

Maintenance.

on side of cab.

1. Select STOP LIGHT or SER.

11. Stoplights Do Not Operate When Brake

1. Ensure STOP LIGHT or SER.

DRIVE. If problem still exists,

Pedal is Pressed.

DRIVE function has been

go to test step 2.

selected on military light

switch.