TM 5-3800-205-10-2

TROUBLESHOOTING PROCEDURES - CONTINUED

0011 00

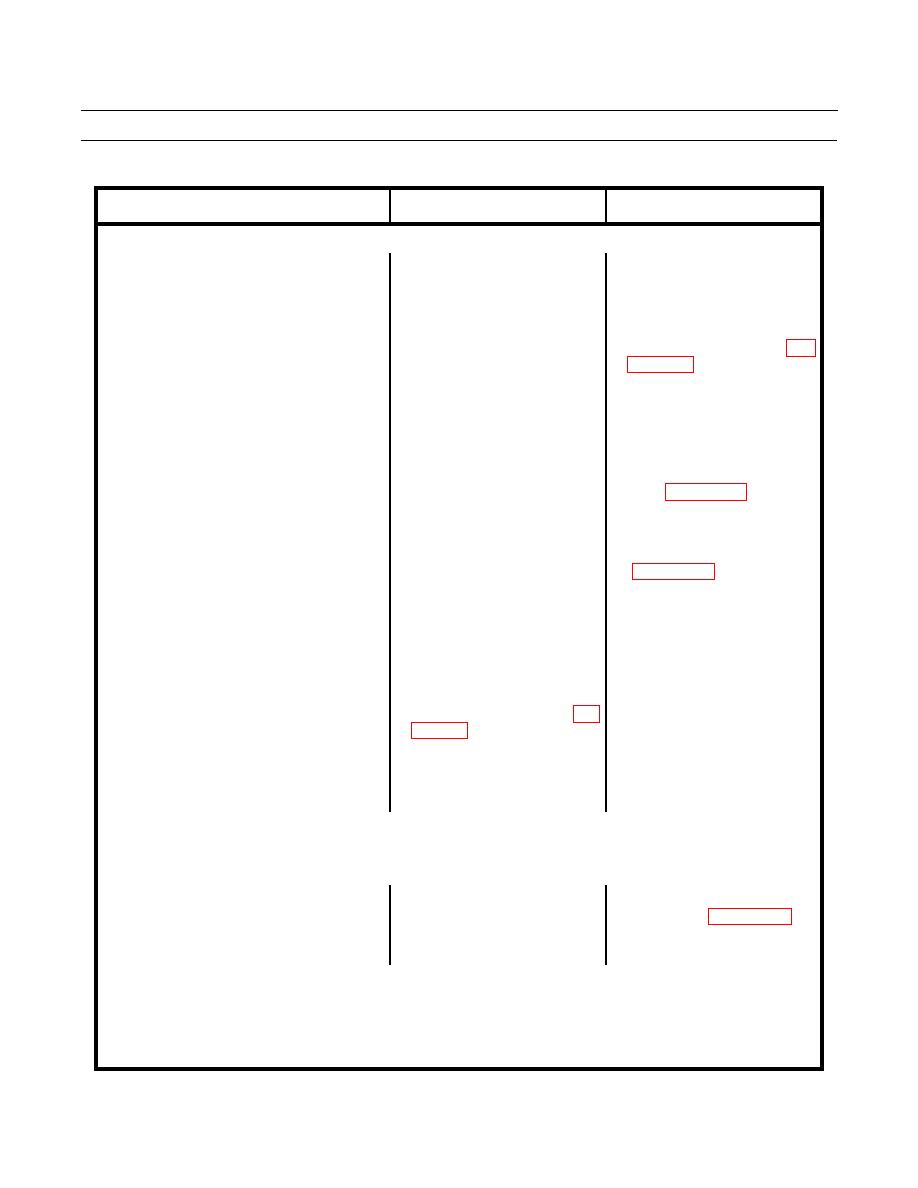

Table 1. Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE - CONTINUED

If connections are okay, notify

6.

Engine Starts But Dies.

Check for loose electrical

connections at engine shutoff

Unit Maintenance.

7.

Engine Starts But Misfires or Runs

Check fuel/water separator for

1. Open fuel/water separator

moisture.

drain valve and drain (WP

Rough After Warmup Period.

exists,

notify

Unit

Maintenance.

8.

Excessive Engine Oil Consumption.

Check for loose oil lines and oil

If oil lines are loose or leaks are

leaks.

found, notify Unit Maintenance.

9.

Excessive Exhaust Smoke (At Normal

1. Check air

filter

service

1. If indicator is red, clean air

indicator.

filter (WP 0014 00) and retest.

Operating Speed).

If problem still exists, go to test

step 2.

2. Check for water in fuel.

2. Drain fuel/water separator

exists,

notify

Unit

Maintenance.

10. Excessive Exhaust Smoke (White)

1. Check and monitor engine

1. Allow engine to warm up to

operating temperature.

operating temperature. If

During Startup.

problem still exists, go to test

step 2.

2. Operate air intake heater (WP

2. If problem still exists, notify

Unit Maintenance.

11. Low or No Engine Oil Pressure Alert

Indicator, Action Light, and Action

Alarm are On.

CAUTION

When action alarm sounds, immediate shutdown of machine is required to prevent damage to

machine.

Check engine oil level.

1. If engine oil is low, fill to

correct level (WP 0013 00). If

problem still exists, notify

Unit Maintenance.

STEERING

WARNING

Hitch and steering movement can reduce clearances suddenly and cause personnel injury. Stop

engine before servicing.