install backup

5.

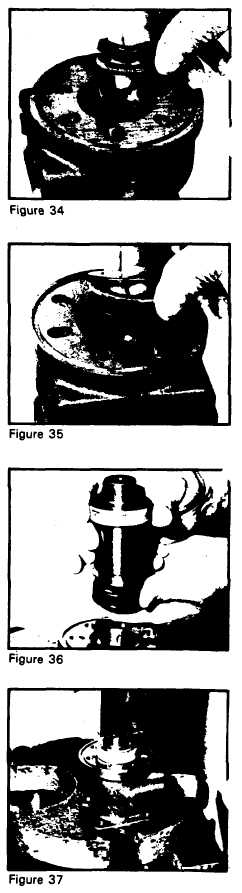

Place housing (15), wearplate sur-

washer & seal

face up, on a clean work surface.

Apply a small amount of clean

grease to inner seal (16). Install

back-up washer (17) then seal

(16) into housing coupling shaft

bore from the wearplate end of

the housing (15). Seat the back-

up washer against the retaining

ring (18) and the seal against the

back-up washer, with the seal lip

facing away from the back-up

washer. SEE FIGURE 34.

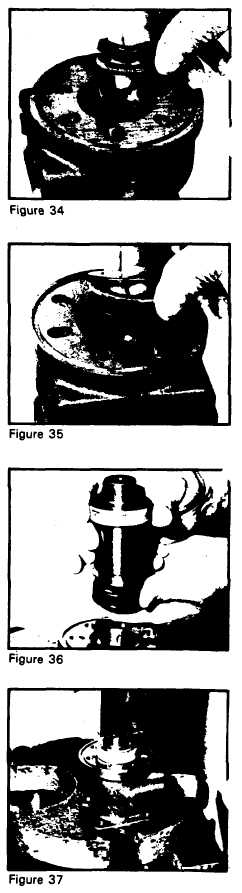

Install thrust

6.

Install a thrust washer (13), the

washers & thrust

thrust bearing (14) and then

bearing

another thrust washer (13) into

the housing (15) inner bearing

bore until they are seated at the

bottom of the bore. SEE FIGURE

35.

press in bearing

7.

Press a new bearing (12) into the

housing (15) inner bearing bore,

from the wearplate face end,

using bearing mandrel (special tool

SEE FIGURE 1, Page 7A) against

the lettered end of the bearing

shell. Take care during this pro-

cedure that the housing is square

with the press base and that the

bearing is not cocked. The bearing

mandrel will control the bearing

press depth to the required

1.618/1.598 inches

(41.10/40.59mm) from the

wearplate face of the housing.

SEE FIGURES 36 and 37.

NOTE

NOTE: If the bearing mandrel

shown is not available, alternate

methods may be used to press in

the bearing but the bearing depth

location must be maintained.

17