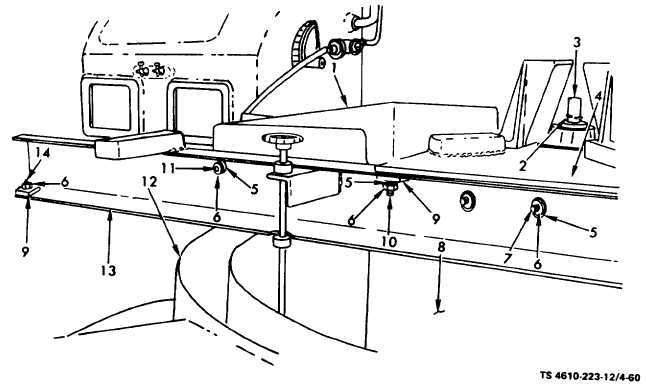

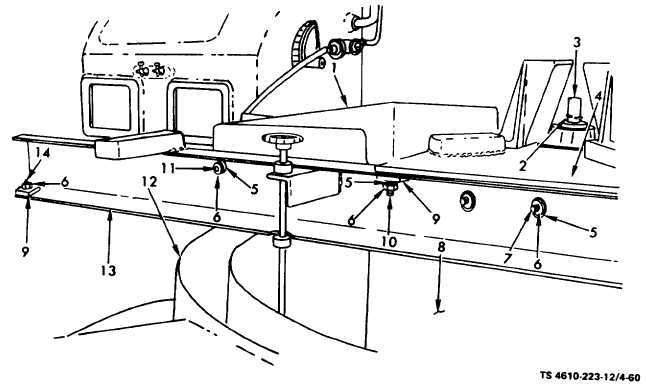

TM 5-4610-223-12

1.

Influent launder

9.

Beveled washer, 3/8 in. (12

2.

Retaining ring

reqd)

3.

Agitator shaft

10. Capscrew, hex hd, 3/8-16 x 1/4

4.

Speed reducer mtg plate

in. (8 reqd)

5.

Lockwasher, split, 3/8 in.

11. Screw, mach, fils hd, 3/8-16 x

(24 reqd)

1-1/4 in. (8 reqd)

6.

Nut, hex, 3/8-16 (24 reqd)

12. Effluent launder

7.

Screw, mach, fils hd, 3/8-16

13. Bridge rail (2 reqd)

x 1 in. (4 reqd)

14. Capscrew, hex hd, 3/8-16 x

8.

Downcomer

1-1/4 in. (8 reqd)

Figure 4-60. Influent Launder, Speed Reducer Mounting Plate, Downcomer and Bridge Rails.

c.

Installation.

(1)

Position effluent launder (12, fig. 4-60) in erdlator tank and support it until it can be secured to bridge rails.

(2)

Position bridge rails (13) on erdlator tank and secure them with screws (14), beveled washers (9), and nuts

(6).

(3)

Install effluent launder supporting rods (para 4-80) and effluent launder to wet well connecting tube (para 4-

74).

(4)

Install downcomer. (Refer to direct support maintenance.)

4-131