install rotor set &

18.

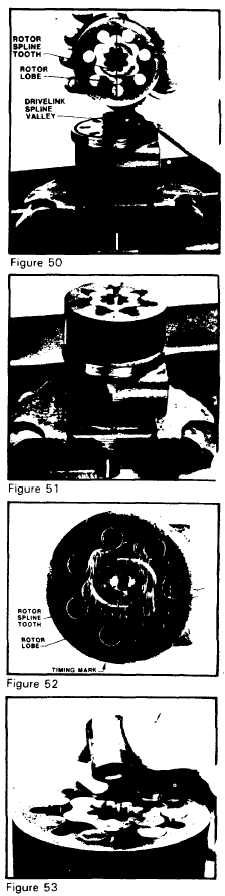

Locate on the rotor (6A) the only

wearplate on

two spline teeth, 1800 apart, that

housing

are diametrically aligned (on the

same center line) with two rotor

lobes. SEE FIGURE 50. Take the

rotor set (6), seal ring (5) and

wearplate (7) as a unit and align

these two just located rotor spline

teeth to mesh with the two drive

link (8) spline valleys that are

diametrically aligned with the

timing mark on the coupling shaft

(11) and install this unit onto the

housing (15) with the wearplate

against the housing. SEE FIGURE

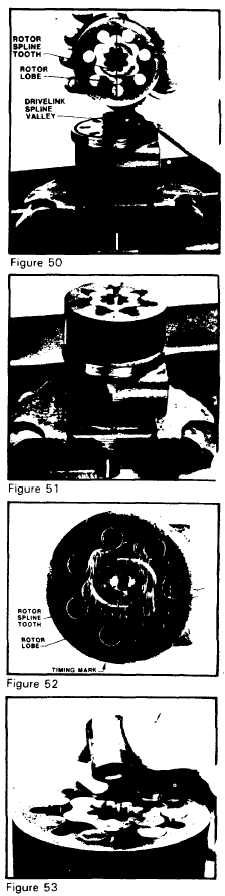

51. With the rotor set (6) now

correctly in mesh with the drive

link, rotate the rotor set (6)

wearplate (7) drive link (8) and

coupling shaft (11) to align the

stator (6B) and wearplate bolt

holes with the bolt holes in the

housing. SEE FIGURE 52.

CAUTION

CAUTION: Be careful not to

disengage the rotor, drive link or

coupling shaft while aligning bolt

holes as this could affect the

timing you just achieved.

CAUTION

CAUTION: The meshing of the

precise rotor (6A) teeth with the

precise drive link (8) spline valleys

as described above is absolutely

crucial to a correctly timed and

functional MAF TorqmotorTM.

Misalignment by one spline tooth

will be indicated by the timing

mark on the coupling shaft (11)

being radically 450 from the

specified rotor lobe. Refer to

"Final Checks" Page 25.

install drive link

19.

Install drive link spacer/washer (4)

spacer/washer

into the rotor spline cavity onto

the end of the drive link (8). SEE

FIGURE 53.

21