TM 10-4610-310-14

0037 00

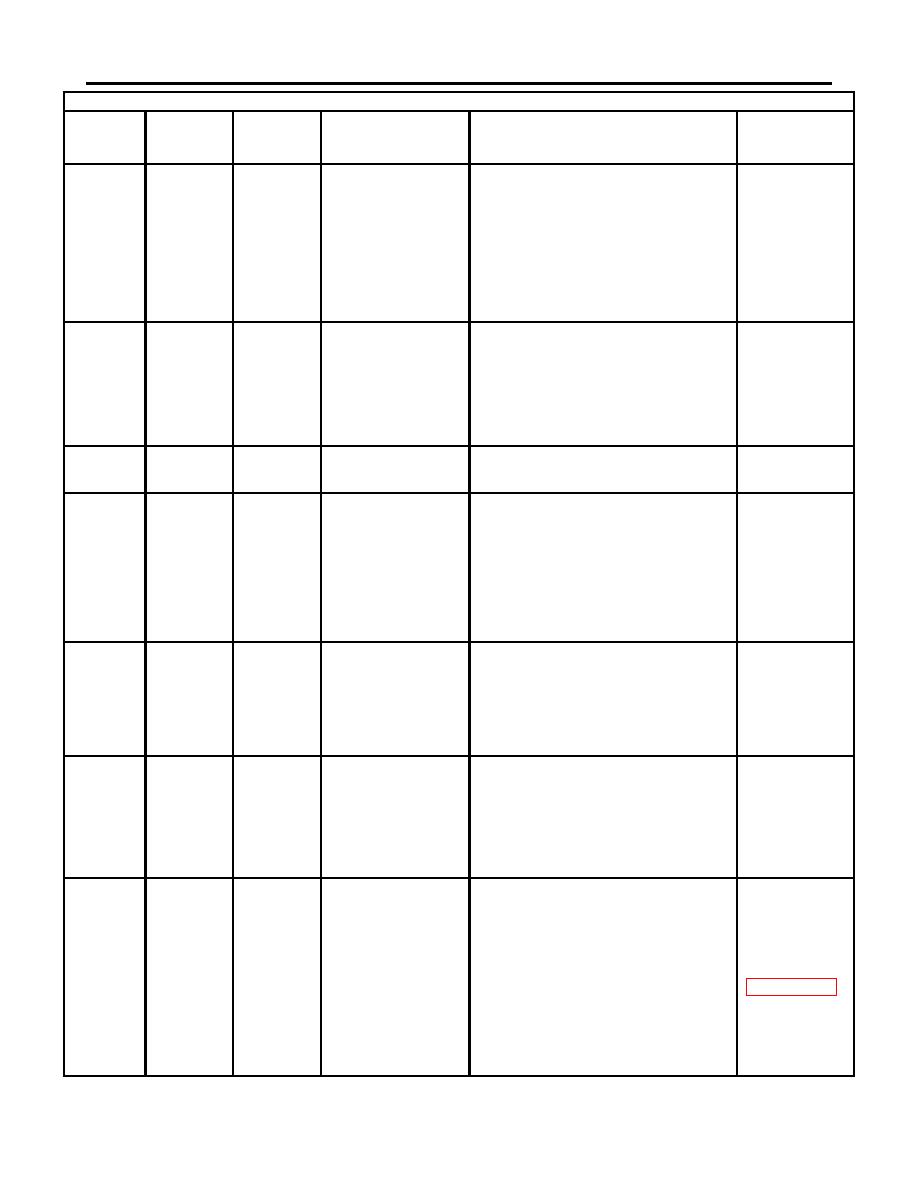

Table 1. Preventive Maintenance Checks and Services.

ITEM TO BE

EQUIPMENT

ITEM NO.

INTERVAL MANHOUR CHECKED OR

PROCEDURE

NOT READY/

SERVICED

AVAILABLE IF

Damage that

Inspect all electrical cables, hoses,

would prevent

High-pressure pump piping for cuts, wear, nicks, kinks,

operation or

9.

Before

breaks, exposed wires, etc. Inspect for

module

creates safety

loose fasteners and fittings.

hazard.

Inspect all electrical cables,

connectors, for cuts, wear, nicks,

Inoperative

breaks, exposed wires, etc. Inspect for

control switches

10.

Before

Control module

loose fasteners and fittings. Inspect

and indicators.

hour meter, indicators, and switches for

damage.

Control module pilot

After energizing CB1, press each pilot

11.

Before

light lamps

light for lamp test

If operating the unit for the very first

time, ensure the RO simulator is

removed and the membranes are

Damage that

Reverse Osmosis

loaded.

12.

Before

would prevent

(RO) element

Inspect all electrical cables, hoses,

operation

module

tubing for cuts, wear, nicks, kinks,

breaks, etc. Inspect for loose fasteners

and fittings.

Inspect all electrical cables, hoses, and

Damage that

tubing for cuts, wear, nicks, kinks,

Chemical injection/

13.

Before

breaks, exposed wires, etc. Inspect for would prevent

cleaning module

loose fasteners and fittings. Inspect for operation

leaks during operation.

Inspect all electrical cables, hoses,

connections for cuts, wear, nicks,

Service pumps (raw

breaks, exposed wires, etc. Inspect for Damage that

water, booster,

14.

Before

loose fasteners and fittings.

would prevent

backwash,

operation

distribution)

Inspect filler/discharge fittings for

corrosion and cracks, loose or missing

bolts. Inspect tank for cuts, tears, and

Collapsible fabric

punctures.

Class III leak

15.

Before

tanks

Check handles for cuts and tears;

secure bonding to tank. Inspect zippers

for proper operation on fabric

collapsible tanks.

0037 00-5