TM 10-4610-310-14

0037 00

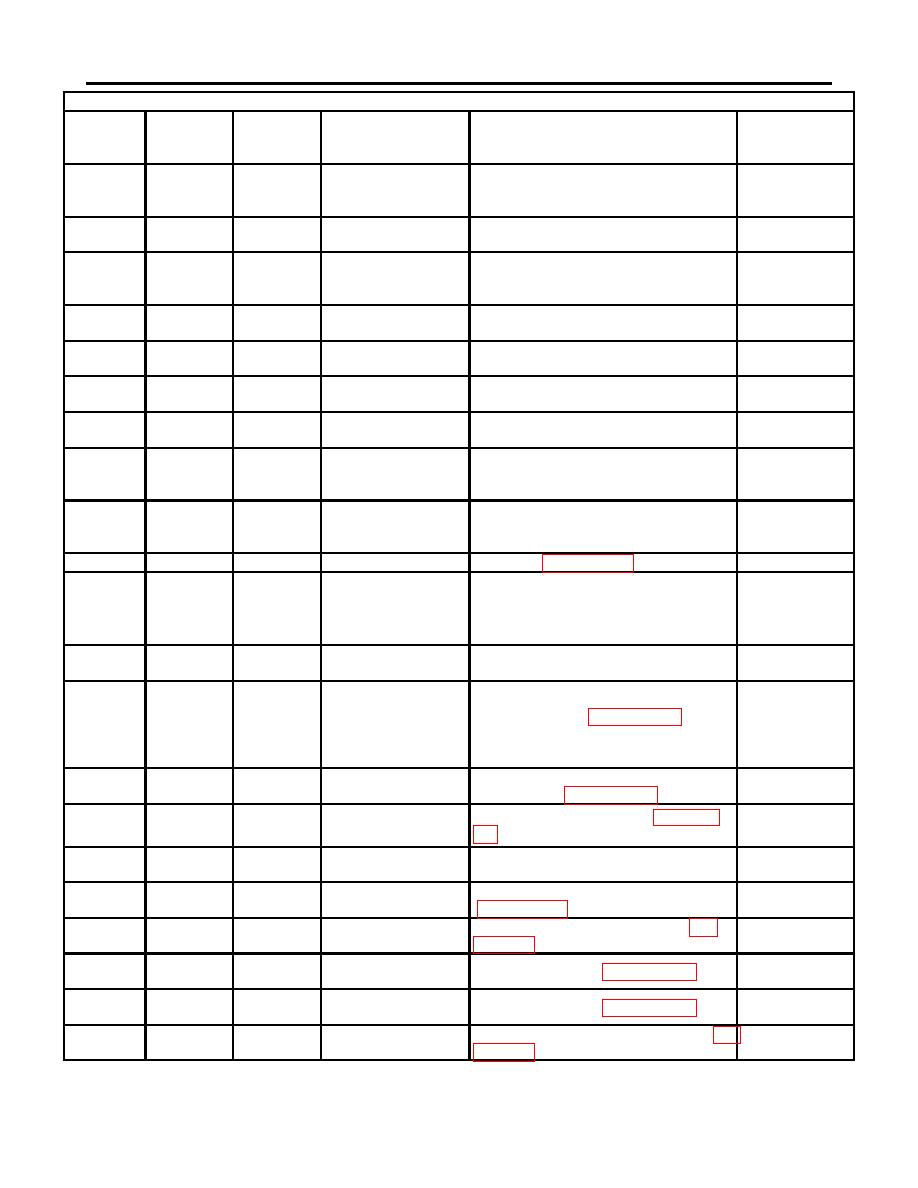

Table 1. Preventive Maintenance Checks and Services.

ITEM TO BE

EQUIPMENT

ITEM NO.

INTERVAL MANHOUR CHECKED OR

PROCEDURE

NOT READY/

SERVICED

AVAILABLE IF

Check for cuts, tears, punctures,

Collapsible fabric

Damage is

85.

After

damaged zipper, leaking

water tanks

observed

filler/discharge fittings

Diesel engine oil

Visually inspect oil level and condition

Oil level is low

86.

After

level

of oil

Damage that

Electrical cables and Check for cuts, loose connections, and

87.

After

would prevent

connections

damaged connections

operation

Drain the air tank if shutdown is longer

88.

After

Air shut off assembly

than 48 hrs.

Drain and clean chemical tanks and

89.

After

Chemical tanks

tubing

Chemical injection

Inspect for cracks, breaks,

Class III leaks

90.

After

tanks (3)

and loose fittings.

Rinse the with clean fresh water to

91.

After

LWP unit and tools

prevent corrosion

Inspect the LWP for signs of corrosion. Corrosion that

92.

Weekly

LWP (Corrosion)

Remove corrosion or replace corroding may prevent

part.

operations

Damage that

High-pressure pump Inspect for looseness, damage, cuts,

would prevent

93.

Weekly

plumbing

leaks

operation

94.

Weekly

Air shut off assembly Lubricate (WP 0093 00)

Inspect for rips, tears, or other damage

95.

Weekly

Avoidance Covers

Report damage to unit maintenance.

Inspect the paint on LWP. Touch up

96.

Weekly

Paint

any area with damaged paint.

Beginning

of

Calibrate meters (WP 0048 00 and

97.

deployment

Water quality meters

0049 00)

, or as

required

Initial oil change, notify unit

98.

50 hours*

Diesel engine

maintenance (WP 0093 00)

High-pressure pump Perform initial oil change, (WP 0041

99.

50 hours

oil

The first 50

Valve clearance

Adjust valve clearance

100.

hours

Change oil, notify unit maintenance

101.

100 hours*

Diesel engine - oil

Diesel engine air

Inspect and change as needed (WP

102.

100 hours

filter

Diesel engine fuel

103.

100 hours

Remove and clean. WP 0093 00.

strainer

Diesel engine air

104.

100 hours

Remove and clean. WP 0090 00.

shutoff - vent plug

Diesel engine fuel

Drain fuel, notify unit maintenance (WP

105.

Monthly*

tank

0037 00-10