TM 10-4610-310-14

0037 00

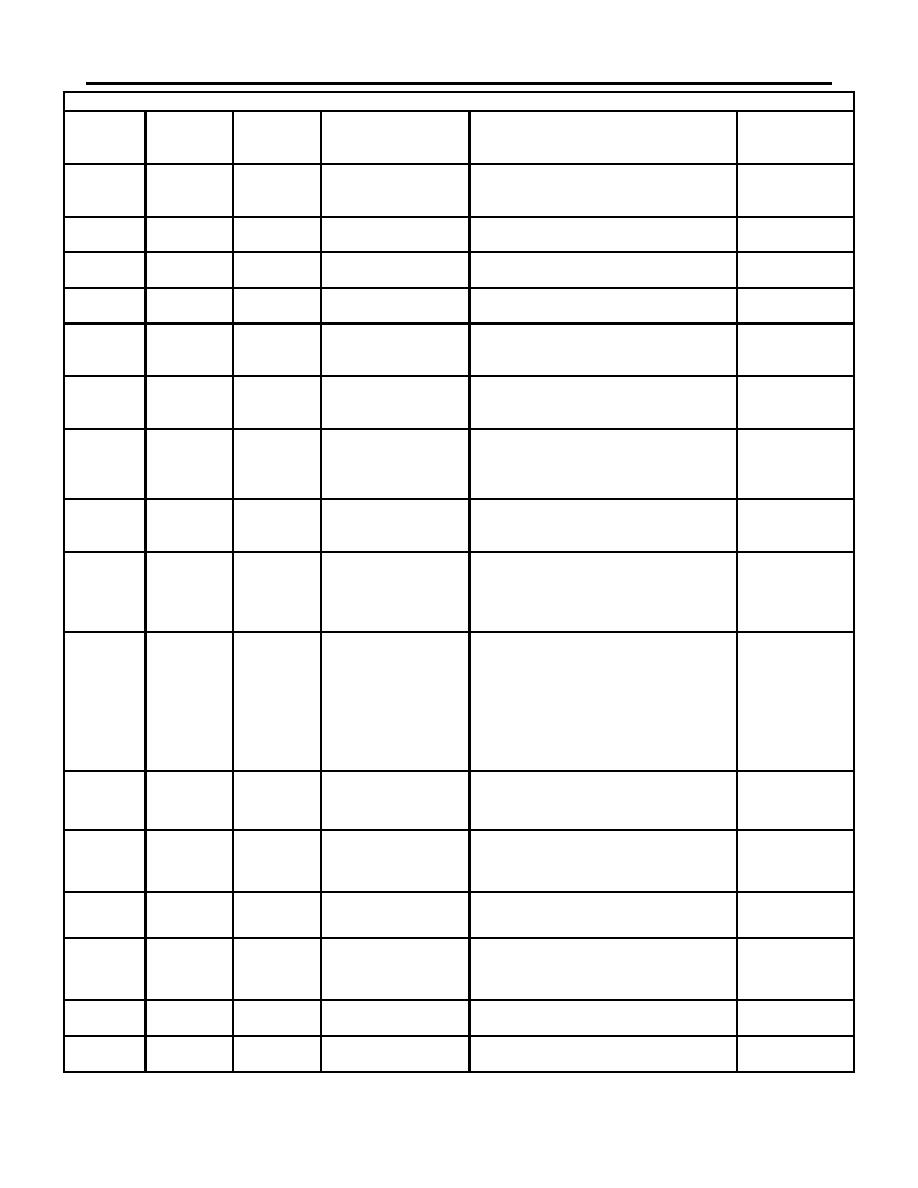

Table 1. Preventive Maintenance Checks and Services.

ITEM TO BE

EQUIPMENT

ITEM NO.

INTERVAL MANHOUR CHECKED OR

PROCEDURE

NOT READY/

SERVICED

AVAILABLE IF

Inspect for function, connections,

52.

Before

RO pressure gauge broken glass.

RO pressure vessel

Inspect for damage

53.

Before

snap ring

Chemical cleaning

Inspect for cracks, breaks, and loose

54.

Before

Leaky tank.

tank

fittings.

Chemical injection

Inspect for cracks, breaks, and loose

55.

Before

Leaky tanks.

tanks (3)

fittings.

Chemical

Damage that

56.

Before

Inspect for leakage, looseness

injection/cleaning

would prevent

check valve

operation

Chemical

Inspect for leakage, looseness,

57.

Before

injection/cleaning 3-

function

way ball valve

Chemical

Damage that

Inspect for leakage, looseness,

injection/cleaning

58.

Before

would prevent

tank outlet ball valve

function

operation

Chemical

59.

Before

Inspect for damage, clogging.

injection/cleaning

strainer

Damage that

Cleaning tank

Inspect for damage, corrosion, wiring

would prevent

60.

Before

immersion heater

operation

Inspect for damage, wiring, leakage,

Any one of the

and function. Inspect for loose

three pumps will

Chemical

mounting nuts. Inspect for cracked or

not supply

61.

Before

broken fittings. Listen for unusual

injection/cleaning

chemical to the

noises during operation. Notify unit

pumps

purification

maintenance to replace malfunctioning

cycle.

pump.

Chemical injection

Inspect for leakage, damaged, cuts,

There is leakage

62.

Before

chemical tanks

dents

at connections.

Heater does not

63.

Before

Cold weather kit

Check heating operation

work in cold

weather

Loose mountings, torn rubber

64.

Before

Priming Pump

Will not prime

diaphragm.

Mildew in

Inspect the tanks for tears, holes, loose

65.

Before

Fabric Tanks

product tank or

fittings, cleanliness and mildew.

damage.

UF differential

66.

During

Check the pressure reading

30 psi or higher

pressure gauge

High-pressure pump Inspect for burrowing if operating on

67.

During

module

soft ground.

0037 00-8