TM 10-4610-310-14

0037 00

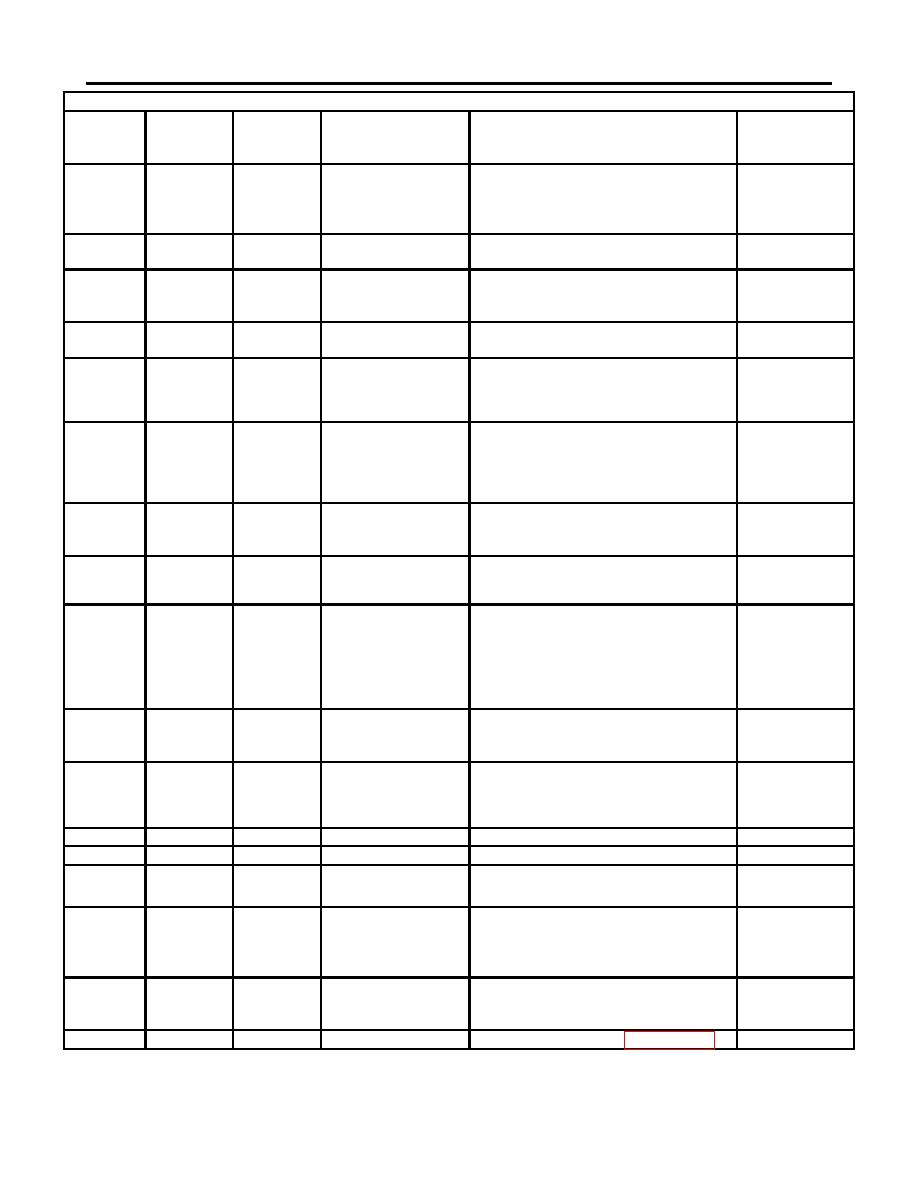

Table 1. Preventive Maintenance Checks and Services.

ITEM TO BE

EQUIPMENT

ITEM NO.

INTERVAL MANHOUR CHECKED OR

PROCEDURE

NOT READY/

SERVICED

AVAILABLE IF

Leaking at a

High-pressure water

Tighten connections to prevent loss of

high flow rate

68.

During

piping, hoses, and

flow

and low

tubing connections

pressure

High-pressure pump

69.

During

Check and refill as necessary

fuel tank

High-pressure pump

Fuel leak, large

70.

During

Check for fuel and oil leaks

diesel engine lines

oil leak

and engine

Engine shut off -

Check and refill so that the pressure in

71.

During

pressure

the air tank is above 30 psi.

Check fuel level and refill as

72.

During

Engine fuel tank

necessary. Do not remove the fuel

strainer to refill.

Check level and refill as necessary.

Damage that

Inspect for leaks, cracks, and

73.

During

Cleaning tank

would prevent

punctures. Inspect for loose

operation

connections.

Damage that

Chemical injection

Check chemical levels. Check

74.

During

would prevent

tanks

connections for leaks

operation

Chemical injection

Inspect for cracks, breaks, and loose

75.

During

Leaky tanks.

tanks (3)

fittings.

Unusual noise is

Service pumps (raw

heard or

Inspect for leaks, unusual noise, loose

water, booster,

damage that

mountings and fittings. Smell for

76.

During

backwash,

would prevent

possible burning

distribution)

operation

Damage that

Inspect for leakage and damaged

77.

During

Product shutoff valve

would prevent

control

operation

Damage that

Check for leaks and proper operation,

would prevent

78.

During

Distribution nozzle

cap missing

operation

79.

During

Distribution hoses

Check for leaks

Class III leaks

80.

During

Raw water hoses

Check for leaks

Class III leaks

Inspect for function, connections,

81.

During

RO pressure gauge

broken glass.

There is any

High-pressure relief Inspect for rust. Observe for leakage at leakage at relief

82.

During

valve

base of relief valve.

valve union to

piping.

Inspect for leaks and loose equipment.

83.

During

Air shut off assembly Ensure the pressure gauge reads

between 30-100 psi.

84.

After

UF membranes

Perform product flush (WP 0013 00)

0037 00-9