TM 10-4610-310-14

0037 00

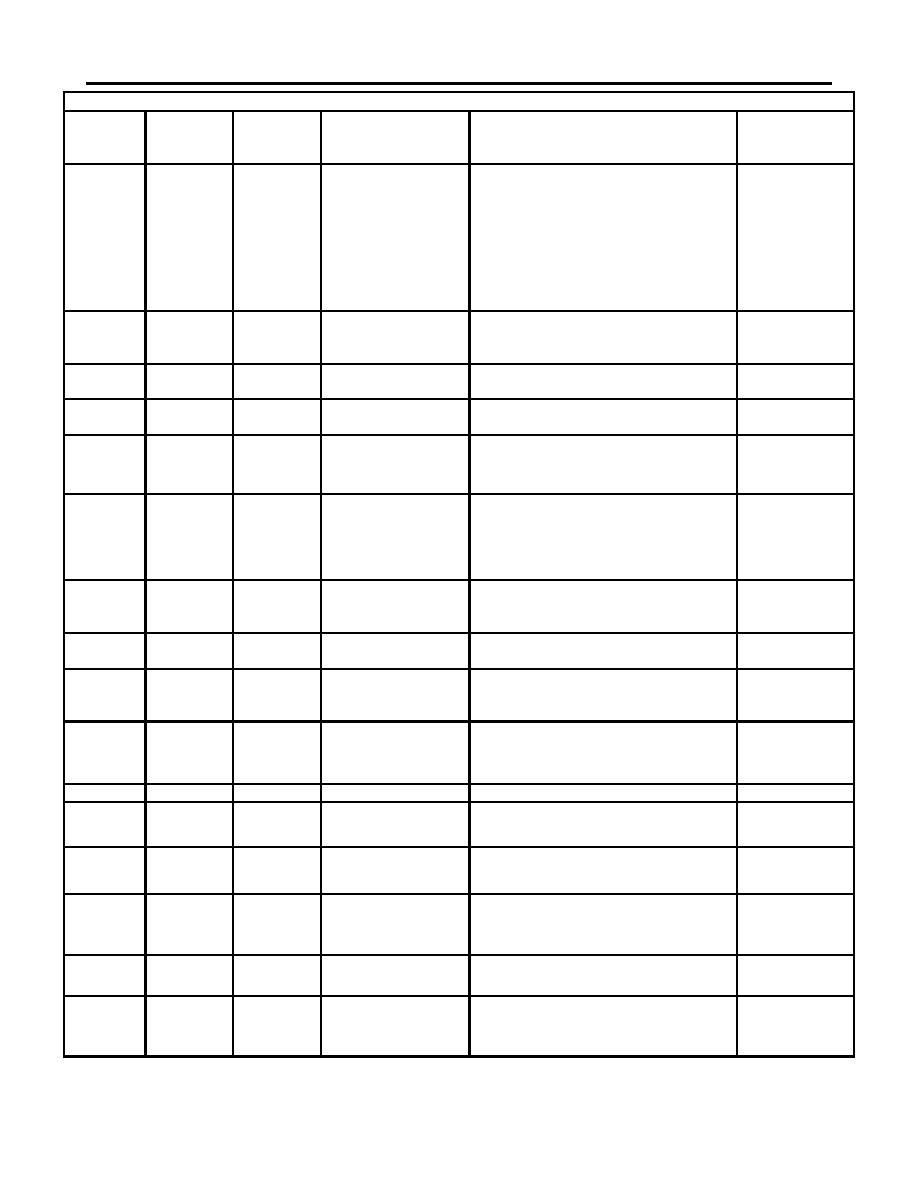

Table 1. Preventive Maintenance Checks and Services.

ITEM TO BE

EQUIPMENT

ITEM NO.

INTERVAL MANHOUR CHECKED OR

PROCEDURE

NOT READY/

SERVICED

AVAILABLE IF

Inspect for damaged connections at

rod and 3kW TQG set. Inspect for

loose, damaged, or missing screw

There is only

Grounding rod,

joints, grounding studs, and driving

one usable

16.

Before

grounding studs, and

section of

bolt. Clean and tighten ground

associated cable

connections and screw joints. Report

ground rod.

unserviceable ground rod to unit

maintenance.

Damage that

17.

Before

Fabric filtrate tank

Inspect for cuts, tears, and punctures.

would prevent

operation

Diesel engine oil

Check and refill as necessary

18.

Before

level

Diesel engine pull

Check for cuts, breaks, and frayed

19.

Before

cord

cord, damaged pull handle.

Check fuel level and refill as

Diesel engine fuel

20.

Before

necessary. Do not remove the fuel

tank level

strainer to refill.

Diesel engine fuel

Inspect for cleanliness. Inspect screen

21.

Before

tank strainer

for holes.

Damage that

Diesel engine fuel

Inspect for leaks, broken connections,

would prevent

22.

Before

and oil lines and

line kinks.

operation

connections

Diesel engine

23.

Before

Inspect for rust, holes, and cracks.

Damage that

Diesel engine

24.

Before

Inspect for function

would prevent

throttle

operation

Inspect the recoil starter for proper

25.

Before

Engine recoil starter

operation by pulling on the starter rope

a few times.

26.

Before

Diesel engine intake Inspect for clogs, dirt

Engine shut off -

Inspect the vent fitting to ensure it is

27.

Before

vent

not clogged.

Engine shut off-

28.

Before

Inspect the drain valve for serviceability

drain valve

Inspect the tank for damage. Open the

Engine shut off-

drain valve momentarily to drain out

29.

Before

Engine tank

any condensation from the tank

Engine shut off -

Ensure proper electrical connections

30.

Before

and serviceability

Engine shut off

Inspect for damaged hoses and fittings.

31.

Before

air lines and fittings

Inspect for clogged hoses and fittings

0037 00-6