TM 5-3800-205-10-2

TROUBLESHOOTING PROCEDURES - CONTINUED

0011 00

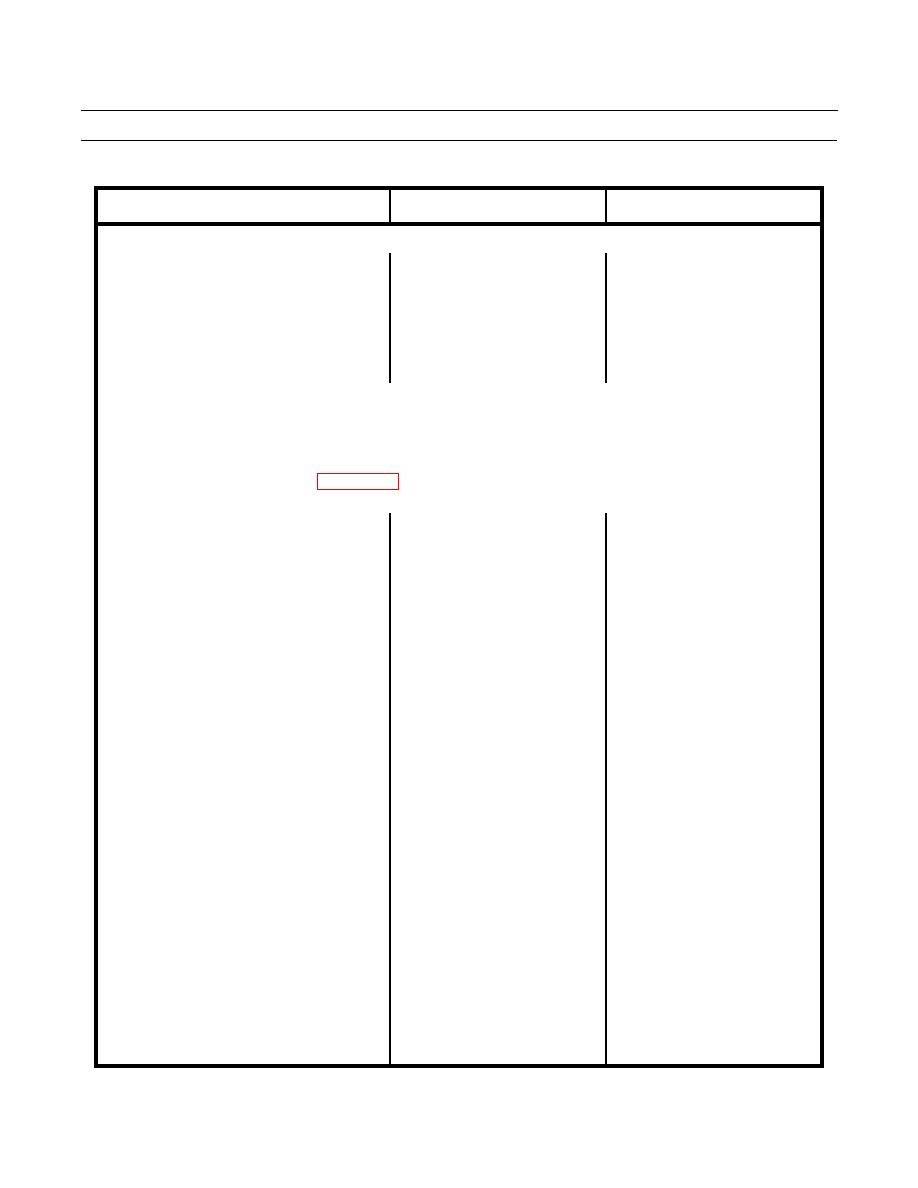

Table 1. Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

WATER DISTRIBUTOR SYSTEM - CONTINUED

2.

Lower Spray Bar Will Not Discharge.

1. Check for water in tank.

1. If tank is empty, fill with water.

If problem still exists, go to test

step 2.

2. Check for blockage or debris at

2. Clear blockage or debris from

nozzles.

nozzles if required. If problem

still exists, go to test step 3.

CAUTION

Do not attempt to open valve by turning indicators. Damage to valve will occur.

NOTE

Refer to component locator (WP 0009 00) and get assistance to aid in checking valve indicator posi-

tion.

3. If indicator is in horizontal

3. Check that indicator on

position, and problem still

Gravity Spray valve is

exists,

notify

Unit

horizontal

to

manifold

Maintenance.

assembly.

3.

Lower Spray Bar Will Not Drain.

Check for blockage at nozzles or

Clear blockages at nozzles or at

at left and right ends of spray bar.

left and right ends of spray bar if

required. If problem still exists,

notify Unit Maintenance.

4.

Lower Spray Bar Will Not Gravity

1. Check that tank is level.

1. If tank is level and problem

still exists, go to test step 2.

Discharge.

2. Check for water in tank.

2. If tank is empty, fill with water.

If problem still exists, go to test

step 3.

3. If switches are in proper

3. Check that PUMP and TANK

position and problem still

FILL SPARGER switches are

exists, go to test step 4.

OFF,

and

PRESSURE

GRAVITY switch is ON.

4. If indicator is in horizontal

4. Check that indicator on

position, and problem still

Pressure Gravity valve is

exists, go to test step 5.

horizontal

to

manifold

assembly.

5. If connections are okay, and

5. Check

for

loose

air

problem still exists, notify

connections

at

Pressure

Unit Maintenance.

Gravity valve.