TM 5-3800-205-10-2

TROUBLESHOOTING PROCEDURES - CONTINUED

0011 00

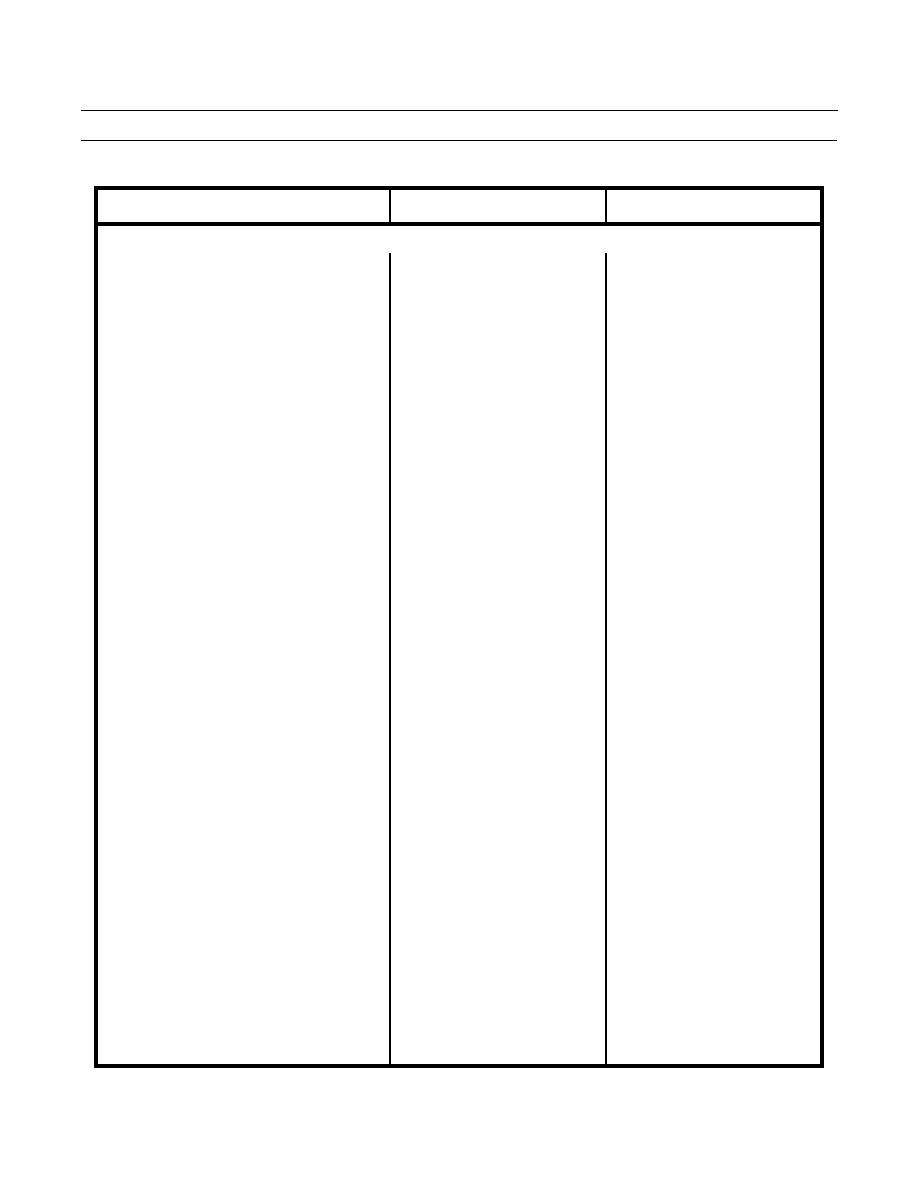

Table 1. Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

WATER DISTRIBUTOR SYSTEM - CONTINUED

7.

No Pressure Discharge From Right

5. Check

for

loose

air

5. If connections are okay, and

Upper Spray Bar - Continued.

connections at air valve.

problem still exists, notify

Unit Maintenance.

8.

Pump Control Lever (Elevator Control

Check for bent or damaged lever.

If lever is bent or damaged, notify

Lever) Will Not Engage.

Unit Maintenance.

Check for bent or damaged lever.

If lever is bent or damaged, notify

9.

Pump Control Lever (Elevator Control

Unit Maintenance.

Lever) Will Not Return to Hold

Position.

1. Check that all tank and piping

1. If tank and piping valve

10. Tank Cannot Be Filled Using

valve switches are closed.

switches are closed and

Pressurized Water Source Through

problem still exists, go to test

Suction Inlet.

step 2.

2. Check that PUMP switch is

2. If PUMP switch is ON and

ON.

problem still exists, go to test

step 3.

3. Check that TANK FILL

3. If switch is ON and problem

SPARGER switch is ON.

still exists, go to test step 4.

4. Check that inlet manual valve

4. Open inlet manual valve if

is open.

required. If problem still

exists,

notify

Unit

Maintenance.

11. Tank Cannot Be Suction Loaded Using

1. Check that foot valve is at

1. If foot valve is at proper depth

(three (3) feet), and problem

Onboard Pump.

proper depth (three (3) feet).

still exists, go to test step 2.

2. Check that inlet manual valve

2. If inlet manual valve is open

is open.

and problem still exists, go to

test step 3.

3. Check that vacuum generator

3. If vacuum generator valve is

valve is OPEN.

open and problem still exists,

go to test step 4.

4. If control lever is in

4. Check that locking lever

FORWARD position and

(elevator direction control

problem still exists, notify

lever) is in FORWARD

Unit Maintenance.

position.

12. Upper Spray Bar Will Not Drain.

Check for blockage at drain hole.

Clear blockage at drain hole. If

problem still exists, notify Unit

Maintenance.